|

LIGHT BULB - PERSISTENT DEVELOPMENT

PLEASE USE OUR A-Z INDEX TO NAVIGATE THIS SITE

PATENT - The epitome of persistence is that having worked tirelessly to perfect a system, that the inventor then follows through with a patent application, to grant.

Only a very few can see a path to making something work, and investing time and money in making it happen, even where the experts of the day say it is impossible. It is often a case of joining the dots that others cannot see. Sometimes even, searching for the dots to be able to join them.

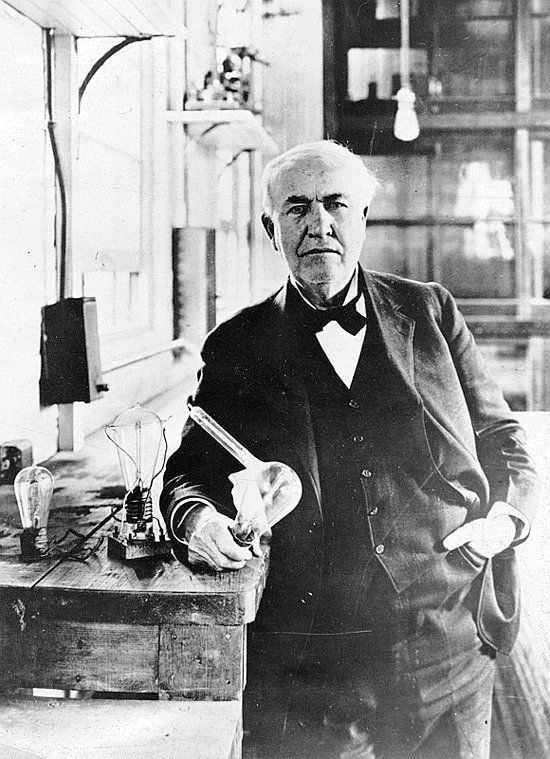

Our

admiration then goes to Thomas

Edison, the inventor of the phonograph and countless other

ideas, for his persistence in the face of the odds against

him. The point is here, that he had the vision to make it work

and then made it work. Twenty-two inventors before him had

failed to produce a workable system.

Thomas Edison began serious research into developing a practical incandescent lamp in 1878. Edison filed his first patent application for "Improvement In Electric Lights" on 14 October 1878. After many experiments, first with carbon in the early 1880s and then with platinum and other metals, in the end Edison returned to a carbon filament. The first successful test was on 22 October 1879, and lasted 13.5 hours.

Edison continued to improve this design and by 4 November 1879, filed for a US patent for an electric lamp using "a carbon filament or strip coiled and connected ... to platina contact wires." Although the patent described several ways of creating the carbon filament including using "cotton and linen thread, wood splints, papers coiled in various ways," Edison and his team later discovered that a carbonized bamboo filament could last more than 1200 hours. In 1880, the Oregon Railroad and Navigation Company steamer, Columbia, became the first application for Edison's incandescent electric lamps (it was also the first ship to use a dynamo).

That is why the saying of Albert Einstein, that "creativity is more important than knowledge," strikes a chord.

More than 95% of the power consumed by a typical incandescent light bulb is converted into heat rather than visible light. Halogen incandescent lamps have higher efficacy, which will allow a halogen light to use less power to produce the same amount of light compared to a non-halogen incandescent light. Halogen lights produce a more constant light-output over time, without much dimming. A 60w tungsten incandescent is around 2.1% luminous efficient. A Glass halogen is around 2.3%, while a Quartz halogen can have around 3.6% luminosity.

AGAINST

ALL ODDS

They conclude that Edison's version was able to outstrip the others because of a combination of three factors: an effective incandescent material, a higher vacuum than others were able to achieve (by use of the Sprengel pump) and a high resistance that made power distribution from a centralized source economically viable.

TUNGSTEN FILAMENTS + INERT GAS

On 13 December 1904, Hungarian Sándor Just and Croatian Franjo Hanaman were granted a Hungarian patent (No. 34541) for a tungsten filament lamp that lasted longer and gave brighter light than the carbon filament. Tungsten filament lamps were first marketed by the Hungarian company Tungsram in 1904. This type is often called Tungsram-bulbs in many European countries. Filling a bulb with an inert gas such as argon or nitrogen slows down the evaporation of the tungsten filament compared to operating it in a vacuum. This allows for greater temperatures and therefore greater efficacy with less reduction in filament life.

In 1917, Burnie Lee Benbow was granted a patent for the coiled coil filament, in which a coiled filament is then itself wrapped into a coil by use of a mandrel. In 1921, Junichi Miura created the first double-coil bulb using a coiled coil tungsten filament while working for Hakunetsusha (a predecessor of Toshiba). At the time, machinery to mass-produce coiled coil filaments did not exist. Hakunetsusha developed a method to mass-produce coiled coil filaments by 1936.

In 1925, Marvin Pipkin, an American chemist,

patented a process for frosting the inside of lamp bulbs without weakening them, and in 1947, he patented a process for coating the inside of lamps with silica.

COST & CLIMATE CHANGE BANS

Prompted by legislation in various countries mandating increased bulb efficiency, "hybrid" incandescent bulbs were introduced by Philips. The "Halogena Energy Saver" incandescents can produce about 23 lm/W; about 30 percent more efficient than traditional incandescents, by using a reflective capsule to reflect formerly wasted infrared radiation back to the filament from which it can be re-emitted as visible light. This concept was pioneered by Duro-Test in 1980 with a commercial product that produced 29.8 lm/W. More advanced reflectors based on interference filters or photonic crystals can theoretically result in higher efficiency, up to a limit of about 270 lm/W (40% of the maximum efficacy possible). Laboratory proof-of-concept experiments have produced as much as 45 lm/W, approaching the efficacy of compact fluorescent bulbs.

The initial cost of an incandescent bulb is small compared to the cost of the energy it uses over its lifetime. Incandescent bulbs have a shorter life than most other lighting, an important factor if replacement is inconvenient or expensive.

Some types of lamp, including incandescent and fluorescent, emit less light as they age; this may be an inconvenience, or may reduce effective lifetime due to lamp replacement before total failure. A comparison of incandescent lamp operating cost with other light sources must include illumination requirements, cost of the lamp and labor cost to replace lamps (taking into account effective lamp lifetime), cost of electricity used, effect of lamp operation on heating and air conditioning systems.

When used for lighting in houses and commercial buildings, the energy lost to heat can significantly increase the energy required by a building's

air conditioning system. During the heating season heat produced by the bulbs is not wasted, although in most cases it is more cost effective to obtain heat from the heating system. Regardless, over the course of a year a more efficient lighting system saves energy in nearly all climates.

Measures to ban light bulbs have been implemented in the European Union, the United States, Russia, Brazil, Argentina, Canada and Australia, among others.

In Europe, the EC has calculated that the ban contributes 5 to 10 billion euros to the economy and saves 40 TWh of electricity every year, translating in CO2 emission reductions of 15 million tonnes.

Objections to banning the use of incandescent light bulbs include the higher initial cost of alternatives and lower quality of light of fluorescent lamps. Some people have concerns about the health effects of fluorescent lamps.

SERIOUS RESEARCH

Thomas Edison began serious research into developing a practical incandescent lamp in 1878. Edison filed his first patent application for "Improvement In Electric Lights" on 14 October 1878. After many experiments, first with carbon in the early 1880s and then with platinum and other metals, in the end Edison returned to a carbon filament.

The first successful test was on 22 October 1879, and lasted 13.5 hours. Edison continued to improve this design and by 4 November 1879, filed for a US patent for an electric lamp using "a carbon filament or strip coiled and connected ... to platina contact wires." Although the patent described several ways of creating the carbon filament including using "cotton and linen thread, wood splints, papers coiled in various ways," Edison and his team later discovered that a carbonized bamboo filament could last more than 1200 hours.

In 1880, the Oregon Railroad and Navigation Company steamer, Columbia, became the first application for Edison's incandescent electric lamps (it was also the first ship to use a dynamo).

COMMERCIAL

PRE-HISTORY

In 1859, Moses G. Farmer built an electric incandescent light bulb using a platinum filament. He later patented a light bulb which was purchased by Thomas Edison.

Incandescent light bulbs consist of an air-tight glass enclosure (the envelope, or bulb) with a filament of tungsten wire inside the bulb, through which an electric current is passed. Contact wires and a base with two (or more) conductors provide electrical connections to the filament. Incandescent light bulbs usually contain a stem or glass mount anchored to the bulb's base that allows the electrical contacts to run through the envelope without air or gas leaks. Small wires embedded in the stem in turn support the filament and its lead wires.

If a light bulb envelope leaks, the hot tungsten filament reacts with air, yielding an aerosol of brown tungsten nitride, brown tungsten dioxide, violet-blue tungsten pentoxide, and yellow tungsten trioxide that then deposits on the nearby surfaces or the bulb interior.

The advantage of the coiled coil is that evaporation of the tungsten filament is at the rate of a tungsten cylinder having a diameter equal to that of the coiled coil. The coiled-coil filament evaporates more slowly than a straight filament of the same surface area and light-emitting power. As a result, the filament can then run hotter, which results in a more efficient light source while lasting longer than a straight filament at the same temperature.

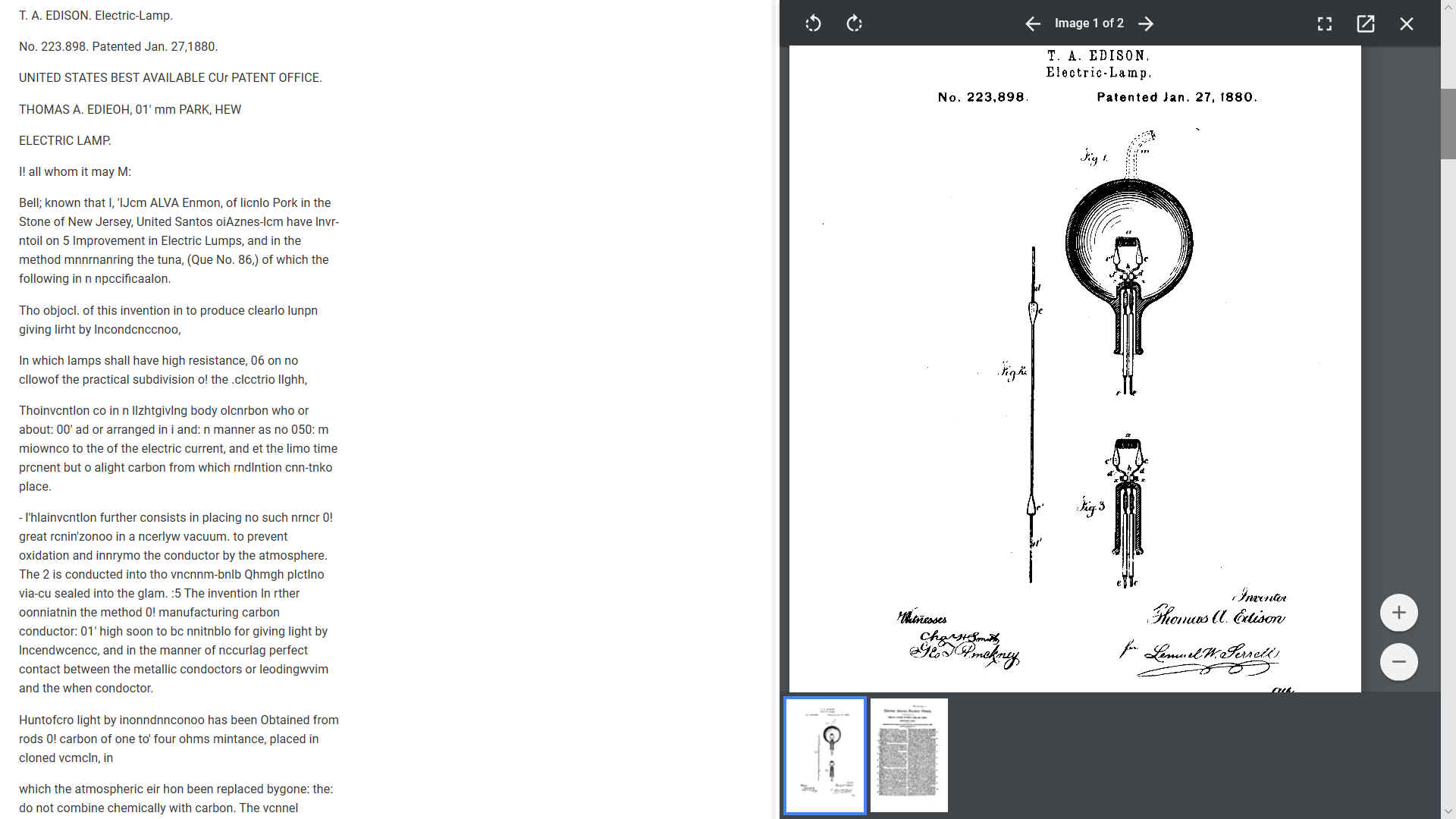

PATENT APPLICATION 1878 No. 223.898 - ELECTRIC LAMP - THOMAS A. EDISON

T. A. EDISON. Electric-Lamp. Patented Jan. 27, 1880. UNITED STATES PATENT OFFICE. (NOTE: from imperfect archive document)

The

object. of this invention in to produce clear lamps giving

light by incandescence, In which lamps shall have high resistance, 06 on no

cllow of the practical subdivision o! the electric

light,

The invention further consists in placing no such nrncr 0! great rcnin'zonoo in a near vacuum to prevent oxidation and innrymo the conductor by the atmosphere. The 2 is conducted into the vacuum-bulb Qhmgh plctlno via-cu sealed into the glam. :5 The invention In other oonniatnin the method 0! manufacturing carbon conductor: 01' high soon to bc nnitnblo for giving light by incandescence, and in the manner of making perfect contact between the metallic conductors or leading wvim and the when conductor.

Hunt for light by incandescence has been Obtained from rods of carbon of one to' four ohms resistance, placed in cloned vcmcln, in which the atmospheric air has been replaced bygone: the: do not combine chemically with carbon. The vcnnel holding the burner tmcomponod oi grim oomontcd to a mo- -"C base. The connmtion Waco the lead- 4 "I n: and the cerbin has wen obtain-d b! p g the carbon to tho mm. Tho 02dlug-vim have always boon largo, no that. their rmlotnnoc shall bo many times loss than tho in general, the nttcmptn of pre- 5 vionn pcrnonn have buen torcdnm U10 olthc mrbon rod. The diaadven tngcn of follow in: this preetioo m that. a lamp ha hm Onctoionr ohms miatnncc cannot be vorkcd in Mt numbers in multiple on: without. the em- 5 F ament of main conductors of enormous dim; than, owing to the low rrniatnnoo of mp, Else lmlm mm must be 0! m dimension-no good conductors, and n l.- globc cannot be kept tight. ct the plncn 1r era the wimpin cod no cemented; honon tho urban iuconnnlnod, bccnnno there must ho n1- mont o perfect vacuum to render the carbon stable, onpccinlly vhencnch carbon inuncll in mnndhi hin electrics! rcslnunon.

Thcnaoo gun in the rconivcrn than:- do monpbcrio prcmure, although M min: the carbon, ncrvcn todcnu-cy it in time by air washing," or the nutrition produced by the rapid of tho air over the slightly-o0- hcront. highly-heated nnrlacc of the when. I have reversed this practice. I have discovered that even a cotton thread properly rnrbonlw and placed in one glass bulb oxhanotod to one-millionth of an atmosphere offer. from one hundred to live hundred ohms renintlnuc to the pun-n50 of the current. and that. it lnnblolutoly stable at very high tempertures; thsz ll the thread bo coiled no a spiral and carbonized. or if my fibronn vegetable cnbntnnoc l will learn a carbon ruidnc after heating in 5 cloned chamber be no coiled, so much an tI0 .thonnend ohm: reoinunoc moy be obw fl without presenting n rndinting'nnrlnco greater than tbrco-lixtecnthn of m inch; tnu. f each fibrous materiel be rubbed with nplut c 00 l poood ol' Imp-black and tar, its resistance :my bo mode high or low. according to amount of lamp-block placed upon it; that en!- bon fllnmcntn mar be made by n oombln of tor and lamp-black. tho lager being 1" vionaly ignited in o closed crucible for loverll l honrn and clherwnrd moistened and kneaded until it makes the consistency of thick putty. Smell picou of this material any be rolled out in the form of vire a small on ncven one-thousandth of an inch in diameter and over a foot in length, and the name my 5.

l W with n non-conducting non'cerbonlzln; nabs-anon and wound on n bobbin, or u n I!- and the tor cnrbonizcd in a cloned chowl her by subjecting it to highland-l m 'P'" nl'ur carbonizntion rculning It. form. be All than forms are l'rngilc nnd cum; "I, clamped to the lending wirm 'dh outlier; loroc to insure good contact and prevent h ing. 1 have diamond that if platinum: are used and tho plulic lamp-block on matorinl be molded mound it. in the auto. on mtion there in nu intimnle union bycon- EST AVAILABLE COPY material be molded around it in the act of carbonization there is an intimate union by combustion and by pressure between the carbon and platine, and nearly perfect contact is obtained without the necessity of clamps; hence the burner and the lending-wires are connected to the carbon ready to be placed in the vacuum-bulb.

When fibrous material is used the plastic lamp-black and tar are used to secure onto the platina before carbonizlng.

By using the carbon wire of such high resistance l mu enabled to use fine platinum wires for leiuling' wires, as they will have a small resistance compared to the burner, and hence will not limit and crack the sealed vac uunl-bulb. llatinu can only be used. no its expansion is nearly the same as that of glass.

By using a considerable length of carbon wire and coiling it the exterior, which Is only a small portion of its entire surface, will form the principal rndiuting-substance; hence I am able to raise the specific heat of the whole of the carbon, and thus prevent the rapid reception and disappearance of the light, which on a plain wire is pn-judicial, as it shows the least unsteadiness of the current by the flickering of the light; but it the current is steady the defect does not show.

It the carbon thread is liable to be distorted during carbonization it is to be coiled between a helix of copper wire. The ends of the carbon or filament are secured to the platina leading-wires by plastic carbonisable material, and the whole placed in the carbonizing-chanr bar. The copper, which has served to prevent distortion of the carbon thread, is afterward eaten away by nitric acid and the spiral soaked in water, and then dried and placed on the glass holder, and a glass bulb blown over the whole, with a lcadin -tuhe for exhaustion by a mercury-pump. is tube, when a high vacuum has been reached, is hermetically sealed.

With substances which are not great] (listorted in carbonising, they may be cost with a non-conducting non combustible substance, which allows one coil or turn of the carbon to rest. upon and be supported by the other.

In the drawings, ignre 1 shows the temp sectionally. n is the carbon spiral or thread. c c are the thickened ends of the spiral formed of the plastic compound of lamp-block and tar. d rl'are the phttina wires. Ii 5 are the clamps, which serve to connect the platina wires, e wanted in the carbon, with the leading-wiles x z, sealed in the glass vacuum bulb. c c are copper wires, connected just outside the bulb to the wires 2: :r. a is the tube (shown by dotted lines) leading to the vacuum-pump, which, after exhaustion, is hermetically sealed and the surplus removed.

Fig. 2 represents the plastic material before being wound into a spiral.

Fig. 3 shows the spiral alter combustion, ready to have a bulb blown over it.

CLAIMS

2. The combination of carbon filaments with a receiver made entirely of glass and conductors passing through the glass, and horn which receiver the air is exhausted, for the purposes set forth.

3. A carbon filament or strip coiled and connected to electric conductors so that only a portion of the surface of such carbon conductors shall be exposed for radiating light, as set forth.

4. The method herein described of securing the platinum contact-wires to the when filament and cerboniain of the whole in a closed chamber, substantially as set forth.

Signed by me this 1st day of November, THOMAS A. EDISON.

Witnesses: B. L. Gun-rm, Jens F. Rmnoum.

LED LIGHT EMITTING DIODES

Oh yes, it gets better ..... Thomas would have loved this. in the 1980s light emitting diodes were developed of increasing size and efficiency for the electronics industry, until by 2020 they were used for industrial, domestic lighting and automotive headlights, all but supplanting the incandescent light bulb.

INSTITUTIONALIZATION

- Study of the

British Board

of Longitude reveals more than just the story of an

institution. It shows how economic interests influenced the

political and scientific activities of a state.

The reasons for this were changes within the "scientific landscape" of the United Kingdom and the concomitant struggle for supremacy in influencing the distribution of state support for the science of astronomy and other related scientific projects, the proof of which is that all the surviving papers come from the archives of the Royal Astronomers and their successors, as if John Harrison's solution was perceived as a threat to their dominance of science. John Harrison was thought of as a maverick, who was grudgingly provided financial support, instead of being generously funded to accelerate development.

We should always then look at the appointment of committees and the interests of their members, that should perhaps be recorded in a book declaring such interests such as to avoid potential conflicts. But there is no point in having such a book if there is no effective policing of the corruption that is inevitable where many can be made from technology for those in positions of trust.

Poor old John Harrison was caught up in this mire of subterfuge. But do not think for one minute, that it is any different today.

305 YEARS AGO - THE BOARD OF LONGITUDE 1714

This is a wonderful story about an ordinary clockmaker from the country who took on the scientific experts in the City of London, the military and the political community and beat them to a standstill.

The bad news for our hero John Harrison, is that it took him all of his life to do so. The good news for millions of sailors is that navigation was improved saving lives, and that John's name will forever be associated with state sanctioned discrimination and political obstruction that became institutionalised.

POLITICAL BLOCKERS - In Britain in 1865, the legislative response to the increasing introduction of self-propelled vehicles on their roads was the Locomotive Act (sometimes known as the Red Flag Act). Amongst a number of provisions, it stipulated that self-propelled vehicles needed to be proceeded with a man walking 60 yards ahead carrying a red flag to warn other road users of the vehicles approach. The objective of powerful stakeholders was to hinder progress to protect their investments in horses, carriages and trains.

THE GOALS

There is little point having such objectives if member nations only pay lip service to the aims in public but stab progress in the back in private, with alternative agendas. We need to root out hypocritical politicians and vote only for those who guarantee to follow through on their promises. Now is the time to vote for the Green candidates and Green parties - no matter how this might affect your investments - for without action against global warming your investments and the lives of your children are worthless.

Our suggestion to prevent politicians doing "U" Turns, is a rule that such breaks from their breaks with election campaigns should mean automatic sacking from any position of office (trust) for 3 years.

Such a Rule, would give the voters some kind of assurance that when they voted a politician in, that they might expect some chance of them following through.

OUR (SUGGESTED) SIX STEPS TOWARD A COOLER PLANET

1. TRANSPORT: Phase out polluting vehicles. Governments aim to end the sale of new petrol, and diesel vehicles by 2040 but have no infrastructure plan to support such ambition. Such infrastructure should exceed the performance of fossil fuel filling stations, prolong EV battery life and provide power grids with a measure of load leveling. Any such system should seek to obviate the provision of millions of fast charge points where implementation could prove to be a logistical nightmare. This may involve international agreement as to energy storage format and statute to steer car makers to collaborate in part in a world of competition.

Marine transport can be carbon neutral given the right policies, with phased transition in specific stages such as not to unduly penalize present investment in LNG shipping and other recent MARPOL compliant IC powered vessels. Future cargo vessel should be at least in part powered by renewable energy, on the road to zero carbon, making allowances for technology catchup.

Air travel powered by kerosene should attract hefty mitigation offset, where low carbon alternatives should be encouraged.

2. RENEWABLES: Renewable energy should replace carbon-based fuels (coal, oil and gas) in our electricity for homes, factories, heating and transport. Coal and nuclear power plants should be phased out.

3. HOUSING: On site micro or macro generation is the best option, starting with new build homes that are both affordable and sustainable by design to replace crumbling housing stocks. Encourage building in timber to provide carbon lock from a renewable natural resource.

4. AGRICULTURE: We need to grow more trees to absorb carbon emissions from a growing population, air travel, and to build new homes. We should promote reductions in food waste and eating of foods that use less energy to produce. Educate children on these matters in schools and via campaigns such as no meat Mondays, should be part of ordinary study.

5. INDUSTRY: Factories should be aiming for solar heating and onsite renewable energy generation. EV parking and even service facilities should be part of new industrial estates as part of any building permissions.

6. POLITICS: - National governing bodies need to adopt rules to eliminate administrative wastages, to include scaling down spending on war machines, increasing spend on educating the public and supporting sustainable social policies that mesh with other cultures. This includes fostering policies and making funds available to close links in the technology chain to make up for lost time. Kleptocratic empire building must cease in the search for natural equilibrium.

SUSTAINABILITY BEGINS AT HOME

What happens on your doorstep is what is happening all over the world. Everyone is empire building, over fishing and dumping waste in our oceans in the belief that a little bit more indulgence won't matter. Yes it will!!

LINKS & REFERENCE

https://en.wikipedia.org/wiki/Incandescent_light_bulb

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2023. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|