|

H2020 FUNDING PROPOSAL CE-FNR-09 HORIZON

Please use our A-Z to navigate this site, where page links may lead to other sites, or see HOME

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ZERO CARBON PERSISTENT MONITORING & RECOVERY - Machines like the proposed 17 meter Pilot SeaVax above could provide sufficient energy to sample the marine environment continuously, also able to transport the sensors and sampling equipment anywhere in the world without using fossil fuels. The head of this machine can be raised out of the water during transit, and lowered to 8 meters to sample microplastics near or on the seafloor or riverbeds - three example positions shown in red. It should be possible to design a head to travel to greater depths, but this will require additional R&D over and above that to achieve what is shown in principle. The turbines depicted are just examples, for example, the raised height may be increased as development proceeds as per example designs shown below and on other linked pages.

NOTE: At the moment this is just a concept, without appropriate levels of funding for research and then for development & build, ZEV research vessels like this will never become a reality. It would be a mistake to think that with a drawing like that above, that the research to make it possible has already been done. According to one of the examiners of such application, he believed that the development work had already been done. Amazing that such high level marking could be so confused - but there we are. We are seeking clarification via the appeals process. But, don't hold your breath! Transparency in decision making is hardly a Union forte.

The Horizon 2020 call we are looking at here is for proposals in the €6m region as a guide against a €13.2m budget, suggesting that two or three projects might get the go ahead. A newly formed consortium, especially to respond to this, developed a proposal tailored to the guide figure.

After two months of search in November and December, a consortium came together with collaborative partners to lay the foundations and further develop means to remove historic accumulations of marine litter from identified hot spots, alongside a strategy to stem the tide of fresh build up.

The deadline for lodging this proposal was Wednesday 22 January, but Monday 20 2020, Brussels time was a safer target. Our consortium lodged on the 21st January. There was an extension to the 23rd January.

The strength of this consortium is that they wish to develop a machine that ticks the EC's boxes as listed below. The partners are hopeful that with the assembled expertise, allied with other expert suppliers in the field, that such a collaborative effort might be given the chance it deserves. We refer to our collaborative partners as The Dream Team.

The consortium proposes to demonstrate the removal of marine litter to highlight how the environment may benefit by the recovery of plastics in marine litter, to enable estimates to be made as to corresponding impacts in terms of ecosystem and economic recovery. The demonstration will be based on a reduced size, prototype machine inspired by the SeaVax concept, in that any such deployment of cleaning machines needs to be carbon neutral if it is to be sustainable as per the SDG terms listed below.

TANK TESTING THE CONCEPT - This is what SeaVax and our water basin looked like in 2016. Seen here is a 1:20 scale (proof of concept) model collecting plastic that was cast on the water to simulate marine litter. Eventually, these vessels would need to be of a size to cope with 8 - 12 million tons of plastic entering the sea every year, operating in numerically containable fleets to transport recovered plastic to land for recycling. That is until we find a replacement for plastic packaging, or adopt more efficient waste disposal schemes. Note that the water basin is open to the elements. See below for development past 2018. We are the only organization that has extracted micro plastics from water like this. Our test tank facilities are ideal for development of the Pilot's collecting head.

PROJECT

AIMS (THE BOXES WE TICK):

1. Clean the seafloor of marine litter in shallow areas to a depth of 8* meters;

2. Clean the surface of near shore waters and harbours of micro and macro marine litter up to a meter in size;

3. Clean the water column of historic micro and macro plastic accumulation to a depth of 3* meters;

4. Identify, or otherwise help to manage discovered ghost fishing nets that may be encountered.

5. Conduct a study over a period of several months by deploying the proposed Pilot cleaning machine (see details below under Design & Construction) at a suitable site to be able to assess the likely impact that such equipment may have in a broader context.

6. Use the proposed Pilot vessel and data from 5. to establish a baseline for up-scaling the concept with a view to tackling blue water accumulations in the 5 gyres.

7. Demonstrate the effectiveness of an automatic and remotely controlled machine capable of collecting plastics and other marine debris as per 1-3 above.

8. Ensure, insofar as practical, that the selective filtration machinery is capable of differentiating between biota and inanimate litter to minimize the environmental impact of cleaning operations.

9. Develop a plan to sort and recycle the collected marine litter in line with the Circular Economy objectives of the EU and UN and the developing plastics strategy.

PROJECT WORK PACKAGES - SELECTIVE FILTRATION MACHINE DESIGN & CONSTRUCTION:

WP1. PROJECT MANAGEMENT

Two stage project management

WP2. PLATFORM DESIGN & COLLECTOR DESIGN & BUILD

To design a mobile platform of a moderate size that may support water filtration equipment and the storage of collected marine litter for transfer to recycling partners. The platform is to be autonomously solar and wind powered with a reserve battery storage capacity.

To tank test a 1:10 scale model of the proposed mobile platform for stability, to include a filtration head and conveyor system to an onboard storage tank.

To upscale the 'filtration head' and conveyor system after scale trials.

Construction of a mobile platform (vessel) at full scale for the installation.

Installation of the marine litter harvesting apparatus on the platform.

Installation of thrusters, storage batteries and other ship systems.

Installation of navigation instruments, to include wiring.

Other fitting out by specialist subcontractors.

Integration of navigation and control hardware and software as part of onboard systems to be able to operate the platform remotely safely in drone mode with autonomous functions in terms of navigation, such as avoidance of other vessels and objects.

WP3. LOCATION DEVELOPMENT (GEO) & OPERATIONS

Launch of the mobile platform (vessel) to include shakedown trials including testing of navigation equipment, energy harvesting apparatus and other vessel systems.

Selection of suitable sites for trials of the marine litter collecting machine.

Operation of the mobile platform to harvest marine litter and collect performance data, to include emptying/transfer of collected marine litter, taking the technology to TRL6

WP4. TOXICOLOGY

Analysis of collected marine litter and plastic.

WP5. DATA ASSIMILATION

Assimilation of data from WP4.

WP6. DATA DISSEMINATION

Dissemination of the results obtained from the project, to include where practical, ocean awareness events.

SOLAR VAWT COMBINATION - Swapping the horizontal 5kW wind turbines for vertical 10kW versions may be possible after development of the mast. VAWTs may be more suitable at more northern latitudes. This 16m (LWL) design features a collecting head approximately 6.75 meters wide. The machine is solar and wind powered for sustainable long endurance tours of duty. In this case featuring vertical axis wind turbines. The operating end of this machine in on the right in this configuration. In the diagram of the 12m transition (from land to sea) above the vessel is working in the opposite direction. It may be advantageous to target larger solids before they degrade into smaller particles to stem the accumulation of plastics in the gyres. After the implementation of such a strategy, ocean cleaning machines might be deployed to tackle historic accumulations. Please note that these drawings are Copyright © November 2019 Cleaner Ocean Foundation and Bluebird Marine Systems Ltd and these are not the advanced VAWTs we will be using.

SOLAR HAWT COMBINATION - A 10kW horizontal turbine setup may be more suitable for litter collecting in open seas, drifting at slightly more than current speed where the vessel catches up waste driven by the rotary sail - or alternatively - uses the energy from the turbine to travel very slowly against the ocean current for short hauls, even where energy wasteful. This is a six-blade design as a rotary sail that you may have noticed lifts higher into the air stream than the Ford Transit rig, also with wider spacing for the round section mast tubes. A VAWT on this mast should work well for anchored sampling operations in northern latitudes. The best method of harvesting waste in various situations will be the subject of several experiments. Please note that these drawings are Copyright © January 2020 Cleaner Ocean Foundation and Bluebird Marine Systems Ltd.

The UK design and build team:

Danny Goldsmith: Naval architect Nelson Kay: Coordination Briggette Dusart: Administration Lloyd Stebbings: Boat builder Richard Whelan: Logistics Jamie Hughes: IT & communications Chris Close: Steerage

SHORT, MEDIUM & LONG TERM IMPACTS

In the short-term:

Such projects might support the implementation of the UN Nation's Decade of Ocean Science for Sustainable Development, and the needs of the Marine Strategy Framework Directive. The objective being to allow those proposing projects with potential to undertake the necessary development for evaluation purposes.

The proposed 'Pilot' vessel is to be designed to achieve removal of up to 90% of macro-plastic litter and a significant fraction of micro-litter in any geographical demonstration area, to reduce the clean-up cost to a local blue economy. This of course depends on currents and tides that may re-litter the chosen test area above local levels, beyond the capacity of a single Pilot machine. For this reason, marinas, harbours and small estuaries are considered to be suitable test areas.

The development of such machines increases the options for stakeholders where such choices are limited at the moment. When developed a wider availability of technologies that might more efficiently remove marine litter may benefit society as well as conserve marine life.

The presence of dedicated ocean close to shore cleaning machines could help raise the awareness of citizens about the importance of disposing of waste responsibly to avoid environmental damage and the high costs for the community (and eventually the tax payer instead of the polluter).

Environmental cleaning machines that meet the criteria are sure to contribute to the sustainable management and protection of marine and coastal ecosystems, helping avoid significant adverse impacts (UN SDG 14), that may well prove to be irreversible if left untended.

In the mid-term:

It is hoped that with the availability of selective cleaning machines, of which one concept is described in this present proposal, that damage from marine litter to the local blue-economy and marine ecosystems services might be significantly reduced, to benefit biodiversity and in turn coastal tourism and food production.

If deployed at appropriate levels as described alongside other means of preventing unregulated discharges from sewers, rivers and waste outfalls, stakeholders might achieve up to 80% reductions of micro-plastics in shellfish or other locally important small marine animals, in treated areas. Once again, raising awareness of the damage that micro fibers are causing in consumers and manufacturers, is seen as being crucial to dealing with the problem.

Such developments are sure to increase scientific knowledge and thus the sharing of marine technology, taking into account the Intergovernmental Oceanographic Commission Criteria and Guidelines on the Transfer of Marine Technology, in order to improve ocean health (UN SDG 14).

Where the quantity of collected marine plastics will rise with routine deployment of cleaning machines, this should go hand-in-hand with methods to reuse the recovered resource in a way that meets the objectives of the European Strategy for Plastics in a Circular Economy.

The development of ocean cleaning machines in timely fashion, not limited to the present concept, might serve as a model to shorten the time span between research and innovation, and implementation of solutions to foster economic value in the blue economy.

In the context of data sharing, we have found that despite the requirement for openness in EC funded research that information is not as freely available as it might be, braking what might be achieved if there were for example a pool of knowledge. In the present proposal the Lead hopes to publish the results of any experiments with the aim of assisting those working and being trained to work within the blue economy, such as to contribute to knowledge of the distribution and fate of marine litter and microplastics.

CAD DESIGN - Beginning in March and ending in May 2019, the Cleaner Ocean Foundation designed an experimental energy harvesting rig to raise and lower wind turbines and get a feel for the hydraulics. The brief was to keep the project low cost (under £5,000) and that the rig should fit into and onto a standard LWB Ford Transit van. The rig included solar fold out wings that are to be tested in 2020, before fitting a slightly larger system to a prototype vessel - an example of which is the Pilot at the head of this page. Click on the diagram above to see this drawing come to life as they cut steel, welded sections and fitted the frame and mast to the donor vehicle.

In the long run:

The deployment of fleets of machines with greater capacity might provide a means of achieving the 80% reduction of micro-plastics and plastics in non-migratory birds species that the EC are concerned with. Where plastic pollution is a global issue, deployment in isolation might not offer a solution. Deployment internationally via cooperation as to territories may achieve the desired reductions.

Locally,

it is possible to deploy relatively low numbers of large cleaning machines

to reduce macro and micro plastics. Specifically, this would be by targeting

river

estuaries.

FRONT VIEW SURFACE MODE - In this diagram the Pilot litter picker is facing towards the viewer. This design is for a 35m2 capacity hopper, hence a wider body and bigger solar panel area. Copyright © diagram 27 November 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

FRONT VIEW SUBSURFACE MODE - As with the diagram above, the Pilot litter picker is facing towards the viewer - but here we see the filtration head lowered to harvest plastics on the sea shores, in rivers or deeper in harbours and marinas. This design features a narrower body and 13.5m2 storage hopper. Copyright © diagram 25 November 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

CONSORTIUM AGREEMENT

TECHNOLOGY PARTNERS

OPEN DATA

SDG 2 – Zero Hunger; SDG 6 – Clean Water and Sanitation; SDG 8 – Inclusive and sustainable economic growth; SDG 9 – Sustainable Industrialisation; SDG 11 – Sustainable Cities and Communities; SDG 12 – Responsible Consumption and Production; SDG 13 – Climate Action; SDG 15 – Life on Land.

FUNDING RATE INNOVATION ACTIONS (IA)

Projects may include limited research and development activities and the funding rate is 70% (except for non-profit legal entities, where a rate of 100% applies).

POLITICS

We remain hopeful that EU politicians and policy makers will want projects like this to run full term, but should the worst happen and Brexit* becomes an issue such as to cause any member to be forced to walk away from participation in their original role, then in that unfortunate situation the partners agree that the technology that they bring to the table leaves with them.

DOCKSIDE COLLECTIONS - For demonstration purposes (only) we might offload plastic to dockside containers using a re-purposed 2nd user waste truck at very low cost. Ideally, we'd be looking for recycling facilities close to where a MultiVax pilot machine comes into ports to offload.

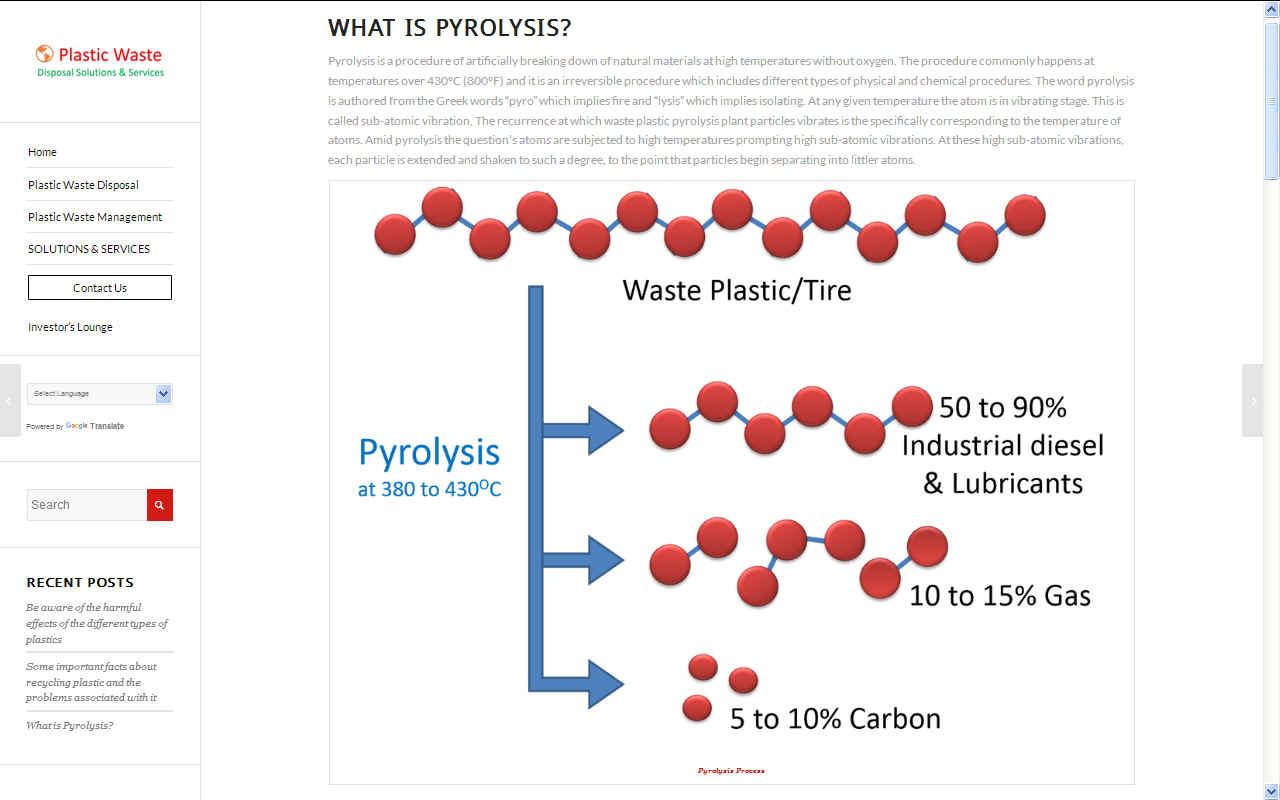

PYROLYSIS - An alternative is to transfer waste at sea to floating re-processing factory ships. But such development would be very costly and involve substantial investment (though a long-term objective perhaps), against close to dock facilities that are commercially available today and simply need to be located sympathetically - along with other recycling of plastics that lend themselves to re-use, such as PET.

ROTARY SAILS - Wind turbines seem to work just as well on land as on the sea as sails to propel vehicles. Inventor, Peter Worsley patented the forerunner of these systems in 1998. The Archinaute on the left was under construction in France in 2019, while the Baltic Thunder on the right came second in a land yacht drag race in 2019 in the Netherlands. The proposed Pilot SeaVax uses two turbines, one at either end of the vessel, each adjustable for height.

ABS American Bureau of Shipping

PROBLEM

- From 2000 to 2012, the National

Marine Fisheries Service reported an average of 11 large whales entangled in

ghost nets every year along the US west coast. From 2002 to 2010, 870 nets

were recovered in Washington (state) with over 32,000 marine animals trapped

inside. Ghost gear is estimated to account for 10% of all marine litter.

LINKS & REFERENCE

https://www.jstor.org/stable/43749297 http://mio-ecsde.org/sdg14-and-marine-litter-what-progress-has-been-made-in-the-mediterranean/

H2020 WORK PROGRAMME - Pilot action for the removal of marine plastics and litter. Cleaner Ocean Foundation Ltd would be interested in forming a consortium for this call and are currently seeking eligible collaborative partners within the EU. This is to further develop the SeaVax concept, to take it to TRL 6, funding permitting.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

"Be the solution, not the pollution."

ABS - BIOMAGNIFICATION - CANCER - CARRIER BAGS - COTTON BUDS - DDT - FISHING NETS - HEAVY METALS - MARINE LITTER - MICROBEADS MICRO PLASTICS - NYLON - OCEAN GYRES - OCEAN WASTE - PACKAGING - PCBS - PET - PETROLEUM - PLASTIC - PLASTICS - POLYCARBONATE POLYOLEFINS - POLYPROPYLENE - POLYSTYRENE - POLYTHENE - POPS - PVC - SHOES - SINGLE USE - SOUP - STRAWS - WATER

Please use our A-Z INDEX to navigate this site, where page links may lead to other sites

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2020. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|