|

PETROCHEMICALS

Without crude oil and the petrochemicals industry, we would not have plastic ocean waste.

That is a cold hard fact, but that does not mean that the 'Industry' is to blame for wanting to use as much of the crude oil they produce as they can. That is plain common sense, such as not to waste a valuable resource.

At

the present time, plastics of all types are entering the

oceans via rivers and other careless disposal or even

accidentally. Estimates range from 8 - 12 million tons a year.

It is the other products that give us our plastic resins and tarmac roads.

SUSTAINABILITY POLICIES & RECYCLING

Who's fault is it then? Who is to blame for petroleum derived plastics entering our marine environment in such vast quantities? Is it the shopper and families throwing waste away with abandon, or is it our policy makers for not realising that this would happen if there were no safety nets?

We are all to blame in some measure, because we did not think ahead. The electorate assumed that the politicians knew what they were doing and the politicians assumed that the manufacturers had all angles covered since they employed technicians. Even the oceanographic institutes had not noticed. Everyone assumed that waste and recycling was enough, but then Captain Charles Moore discovered giant swirls of plastic particles in the oceans. It should not have been there.

Clearly, to this point ocean monitoring was not effective enough, even using satellites from space. So much for NASA and the ESA.

Okay, so we've blamed each other, but we still have a problem. It is only because of responsible reporting that most people who are aware have learned of marine litter. Praise for information sharing must go to the BBC and Sir David Attenborough for the Blue Planet II series.

The Trust and Foundation are not so much concerned with blame than solving the problem. To solve any problem we need to understand the cause. Ultimately, it is the State that must carry the can for allowing its economy to operate in such fashion as to damage marine life in territorial and then international waters.

The State might argue that many other nations were doing the same, but ignorance, or ignoring a problem because others are doing the same, is no excuse.

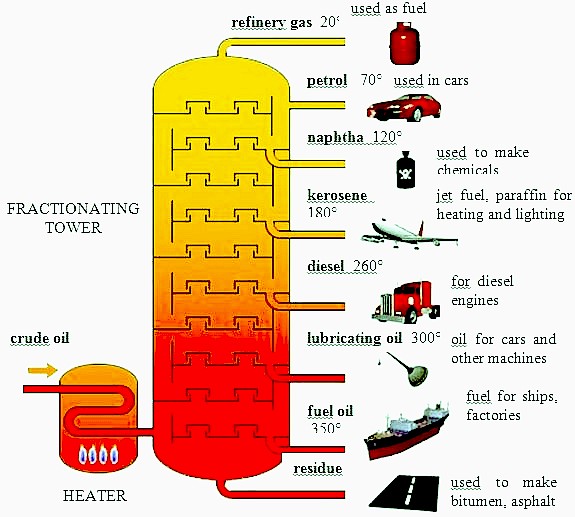

REFINING - 42 gallons per barrel makes about 19½ gallons of gasoline, 9 gallons of fuel oil, 4 gallons of jet fuel, and 11 gallons of other products, including lubricants, kerosene, asphalt, and petrochemical feedstocks to make plastics. That adds up to more than 42 gallons because of something called "refinery gain" - the processing and chemical changes increase the volume.

So how do we make plastic? It all begins with fractional distillation of crude oil.

FRACTIONAL DISTILLATION

The oil refining process starts with a fractional distillation column. Fractional distillation is used for the distillation of crude oil by the petrochemical industry.

Fractional distillation is useful for separating a mixture of substances with narrow differences in boiling points, and is the most important step in the refining process of crude oil.

Very few of the components come out of the fractional distillation column ready for market. They must be chemically processed to make other fractions.

The fractional distillation of the crude oil is the starting point for the manufacturing of gasoline, lubricating oil, diesel, fuel oil, chemicals and plastics.

The mixture boils, forming vapor (gases); most substances go into the vapor phase. The vapor enters the bottom of a long column (fractional distillation column) that is filled with trays or plates.

The trays have many holes or bubble caps (like a loosened cap on a soda bottle) in them to allow the vapor to pass through. They increase the contact time between the vapor and the liquids in the column and help to collect liquids that form at various heights in the column. There is a temperature difference across the column (hot at the bottom, cool at the top).

The substance with the lowest boiling point will condense at the highest point in the column; substances with higher boiling points will condense lower in the

column.

PETROLEUM HISTORY

The modern history of petroleum began in 1846, with the discovery of the process of refining kerosene from coal by Atlantic Canada's Abraham Pineo Gesner. Poland's Ignacy Łukasiewicz discovered a means of refining kerosene from the more readily available "rock oil" ("petr-oleum") in 1852 and the first rock oil mine was built in Bobrka, near Krosno in southern Poland in the following year. These discoveries rapidly spread around the world, and Meerzoeff built the first Russian refinery in the mature oil fields at Baku in 1861. At that time Baku produced about 90% of the world's oil. The battle of Stalingrad was fought over Baku (now the capital of the Azerbaijan Republic).

The first commercial oil well drilled in North America was in Oil Springs, Ontario, Canada in 1858, dug by James Miller Williams. The American petroleum industry began with Edwin Drake's discovery of oil in 1859, near Titusville, Pennsylvania. The industry grew slowly in the 1800s, driven by the demand for kerosene and oil lamps. It became a major national concern in the early part of the 20th century; the introduction of the internal combustion engine provided a demand that has largely sustained the industry to this day. Early "local" finds like those in Pennsylvania and Ontario were quickly exhausted, leading to "oil booms" in Texas, Oklahoma, and California.

By 1910, significant oil fields had been discovered in Canada (specifically, in the province of Alberta), the Dutch East Indies (1885, in Sumatra), Persia (1908, in Masjed Soleiman), Peru, Venezuela, and Mexico, and were being developed at an industrial level.

PLASTICS

Plastics are relatively modern, or rather modern plastics developed from oil distillates are extremely useful to humans as part of societal advancement.

We cannot do without plastics in our modern society. They are incredibly versatile, extending the capabilities of mankind.

In order to keep on using plastics, we need to develop a closed loop recycling ability to include the sea.

The companies listed below control most of the plastic that is produced on planet earth.

* Denotes membership of the AEPW

There is nothing wrong with plastic if it is disposed of carefully. This gives us very good reason to develop a system for making the best use of plastic, and this includes recycling it way more effectively than before.

We cannot afford to waste the plastic that is in our oceans, and we are talking about at least 8 million tons a year of the stuff going out to sea. Though some estimates put it as high as 12 million tons.

FAST FOOD SLOW DEATH - It's not just fast food, it is our exploitative society that is poisoning the planet, without thought for the consequences. We've been living at artificially low prices at the expense of killing other life on earth. Eat cheap now and suffer expensively later, with health services picking up the tab and costing the taxpayer more than if we'd dealt with ocean dumping up front. We are talking here about the consequences of eating toxic fish. Technically, it is possible to remove plastic from seawater. There are two projects currently trying to achieve this, the Ocean Cleanup Projects of Boyan Slat and his giant floating booms, and the Cleaner Ocean Foundation and SeaVax. There are also myriad beach cleaning projects working with thousands of volunteer pickers world wide.

LINKS & REFERENCE

https://www.quora.com/How-much-petrol-kerosene-and-diesel-are-extracted-from-one-gallon-of-crude-oil http://www.theoillab.co.uk/ http://www.kendrickoil.com/how-is-diesel-fuel-made-from-crude-oil/ http://www.petroleum.co.uk/refining

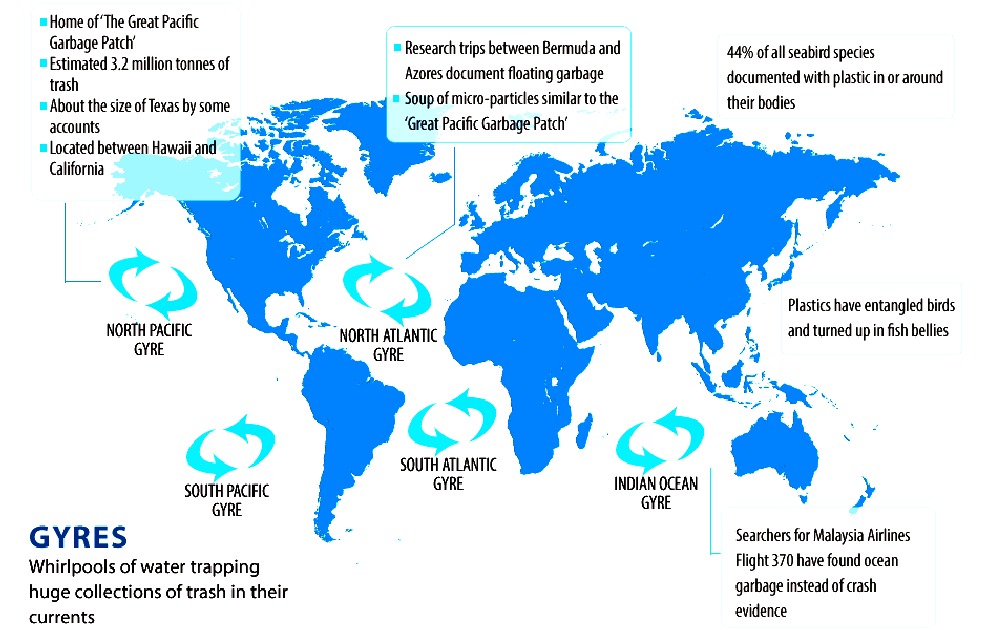

BUILD UP - Plastic has accumulated in five ocean hot spots called gyres, see here in this world map derived from information published by 5 Gyres. All that plastic just floating around is a huge waste of resources in a sustainable sense, where we should be aiming for a circular economy.

ABS - BIOMAGNIFICATION - CANCER - CARRIER BAGS - COTTON BUDS - DDT - FISHING NETS - HEAVY METALS - MARINE LITTER MICROBEADS - MICRO PLASTICS - NYLON - PACKAGING - PCBS - PET - PETROLEUM - PLASTICS - POLYCARBONATE - POLYOLEFINS POLYPROPYLENE - POLYSTYRENE - POLYTHENE - POPS - PVC - SHOES - SINGLE USE - SOUP - STRAWS - WATER

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2019. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|