|

ALPLA - PLASTICS PRODUCERS

ALPLA is an Austrian based plastics manufacturer with its headquarters located in Hard. The company specialises in blow-moulded bottles, caps, preforms, injection moulded parts and tubes.

They are the largest producer of plastic packaging in Europe, having 68 production plants located in Western Europe, with 160 production plants in more than 42 countries globally.

As of 2016, ALPLA had approximately 17,300 employees working for them, with yearly sales of € 3.3 billion Euros in 2018. The company is measured as the leading international firm for plastic packaging and supplies their customers with excellent packaging solutions via their own research division.

Notably, ALPLA operates its own recycling plants and PET Recycling Team with two sites in Austria and Poland, and in the form of joint ventures in Mexico and Germany. The annual capacity of these facilities is around 60,000 tonnes of food-grade rPET. The technology has now become so sophisticated that the production of rPET at Wöllersdorf (Austria) generates only one tenth of the greenhouse gas emissions of virgin materials. Recycling therefore has enormous potential and can play a major role in achieving global climate targets. Well done to ALPLA.

Energy consumption has a significant impact on the total cost of their production as well as on the environment. Their production is based on the responsible and efficient use of energy for several reasons. They believe that a cutting-edge infrastructure is a key factor in energy management. They regularly conduct plant energy assessments in their facilities and carry out modernization work. For example, they recently identified savings potential following a successful assessment of up to 20 per cent.

To reduce CO2 emissions, ALPLA uses renewable energy sources. Their own photovoltaic modules produce electricity for ALPLA production processes worldwide. The Austrian sites obtain a large amount of electricity from alternative sources (water, sun). ALPLA has a cooperation with a wind farm in Mexico, which covers over 60 per cent of its energy demands. This is the kind of thinking that to our way of thinking sets a shining example to other companies in polymers.

We cannot do without plastics in our modern society. They are incredibly versatile, extending the capabilities of mankind. But plastic is getting bad press from a lack of recycling efficiency in many countries where significant quantities are being flushed out to sea via rivers and other coastal dumping.

There is nothing wrong with plastic if it is disposed of carefully. Oil derived plastics are a finite resource and non-renewable demanding special attention, as with the changeover from burning fossil fuels to renewables.

This gives us another good reason to develop a system for making the best use of plastic, and this includes recycling it way more effectively than before. We cannot afford to waste plastic that is in our oceans, and we are talking about at least 8 million tons a year of the stuff going out to sea.

FAST FOOD SLOW DEATH - It's not just fast food, it is our exploitative society that is poisoning the planet, without thought for the consequences. We've been living at artificially low prices at the expense of killing other life on earth. Eat cheap now and suffer expensively later, with health services picking up the tab and costing the taxpayer more than if we'd dealt with ocean dumping up front. We are talking here about the consequences of eating toxic fish. Technically, it is possible to remove plastic from seawater. There are two projects currently trying to achieve this, the Ocean Cleanup Projects of Boyan Slat and his giant floating booms, and the Cleaner Ocean Foundation and SeaVax. There are also hundreds of beach cleaning projects world wide, involving thousands of volunteers.

It's easy to dismiss plastics as cheap and nasty materials that wreck the planet, but if you look around you, the reality is that we depend on it. If you want cars, toys, replacement body parts, medical adhesives, paints, computers, water pipes, fiber-optic cables, and a million other things, you'll need plastics as well.

If you think we struggle to live with plastics, try imagining for a moment how we'd live without them. Plastic is pretty fantastic. We just need to be smarter and more sensible about how we make it, use it, and recycle it when we're done with it.

Most plastics are synthetic, they'd never spontaneously appear in the natural world and they're still a relatively new technology, so animals and other organisms haven't had a chance to evolve so they can feed on them or break them down.

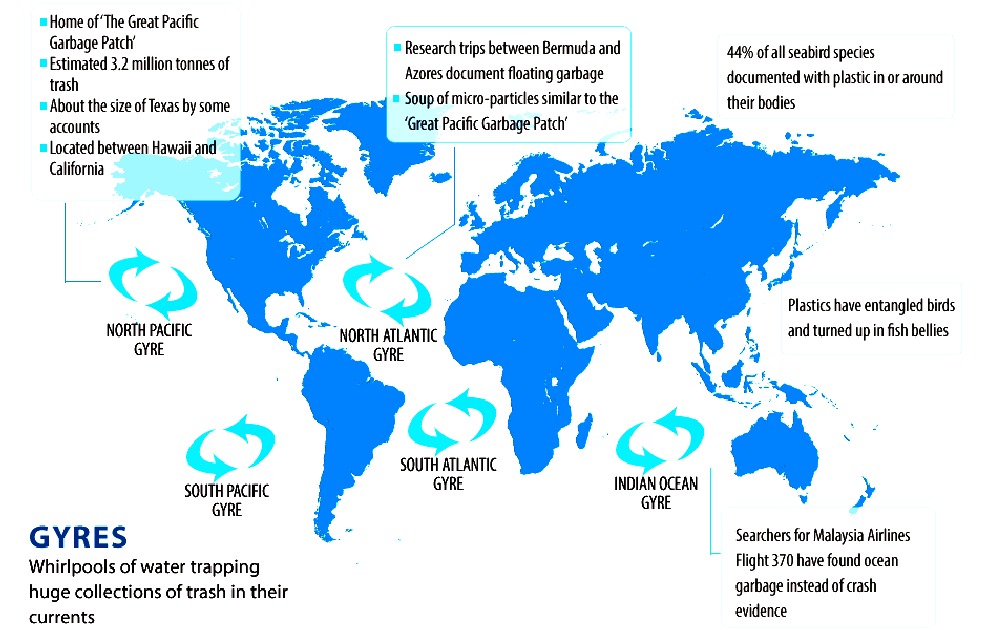

Since a lot of the plastic items we use are meant to be low-cost and disposable, we create an awful lot of plastic trash. Put these two things together and you get problems like the Great Pacific Garbage Patch, a giant "lake" of floating plastic in the middle of the North Pacific Ocean made from things like waste plastic bottles.

How can we solve horrible problems like this? One solution is better public education. If people are aware of the problem, they might think twice about littering the environment or maybe they'll choose to buy things that use less plastic packaging.

Another solution is to recycle more plastic, but that also involves better public education, and it presents practical problems too (the need to sort plastics so they can be recycled effectively without contamination). This is where companies like ALPLA give us a warm feeling inside. They are doing what is needed right now. Governments that dispose of their trash in rivers may want to give this company a call.

A third solution is to develop bioplastics and biodegradable plastics that can break down more quickly in the environment. Soft drinks producers have been looking into this for many years.

CIRCULAR ECONOMICS - ALPLA has reduced their plastic and carbon footprints in operating PET recycling plants like this. Using solar and wind energy as much as possible in the mix is the way to go for sustainability where global warming is an issue. ALPLA get our vote for forward planning in a world that needs adaptive thinking if our children are to have the future they deserve.

LINKS & REFERENCE

https://sustainability.alpla.com/en http://www.polymerdatabase.com/Polymer%20Brands/Plastic%20Manufacturers.html

BUILD UP - Plastic has accumulated in five ocean hot spots called gyres, see here in this world map derived from information published by 5 Gyres. All that plastic just floating around is a huge waste of resources in a sustainable sense, where we should be aiming for a circular economy.

ABS - BIOMAGNIFICATION - CANCER - CARRIER BAGS - COTTON BUDS - DDT - FISHING NETS - HEAVY METALS - MARINE LITTER MICROBEADS - MICRO PLASTICS - NYLON - PACKAGING - PCBS - PET - PETROLEUM - PLASTICS - POLYCARBONATE - POLYOLEFINS POLYPROPYLENE - POLYSTYRENE - POLYTHENE - POPS - PVC - SHOES - SINGLE USE - SOUP - STRAWS - WATER

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2019. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|