|

VW OCEAN PLASTIC AWARENESS SERVICING

Please use our A-Z INDEX to navigate this site, where page links may lead to other sites

|

|||

|

German made VW 1978. |

"MISS OCEAN" has pressed steel body panels 2-pack paint & vinyl wrap.

|

||

|

|

Twin sliding side doors. |

||

|

|

|

||

|

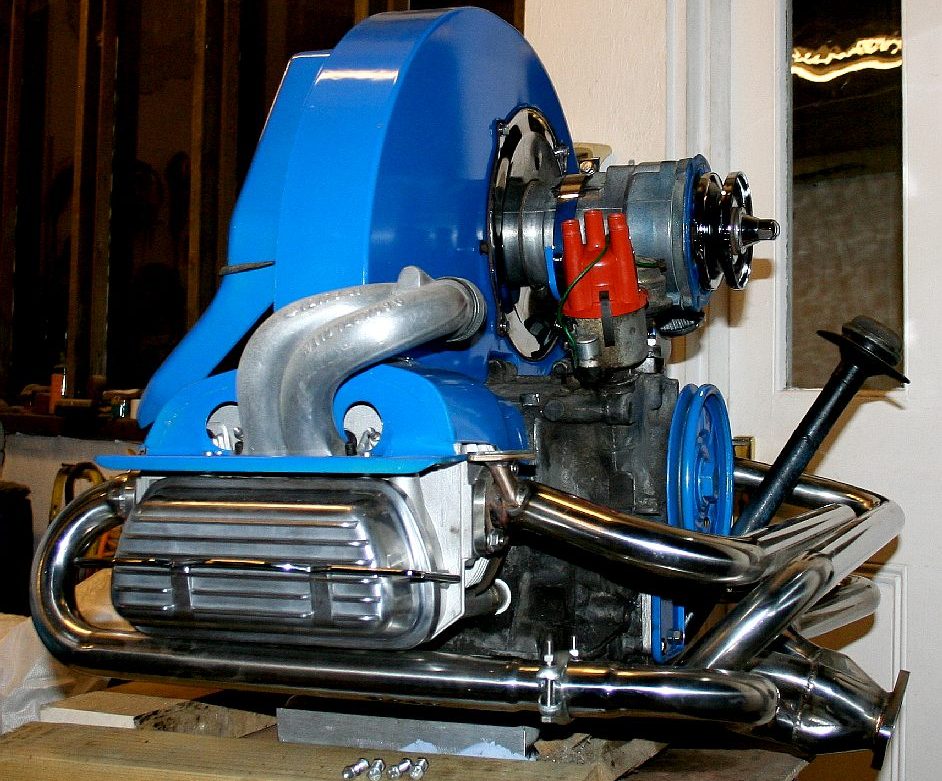

Porsche designed air cooled 4 cylinder engine. |

Forward driving cab with wraparound windscreen. |

||

|

|

|

||

|

Stainless steel custom silent pack exhaust system. |

Wide alloy wheels and eco low rolling resistance tyres. |

||

|

|

|

||

|

|

UK Historic vehicle, Tax & MOT exempted in 2018, custom interior. |

||

|

Modern cars and vans do not have mechanical contacts. Historic vehicles like our surfing bus are old school, meaning that mechanics need to be skilled in setting gaps and timing.

PAINTING PREPARATIONS - Where bodyworks have been substantial, involving the replacement of panels and sections, and putting right older scrapes, there is a lot of blending with polyester filler paste, before getting anywhere near the priming stages.

Correct ignition timing is dependent upon the rest of the ignition system being set up properly. Accurate timing cannot be achieved unless you have sufficient compression, the valve clearances are correct, the ignition contacts (points) gap is correct, the spark plug gaps have been set correctly and the fuel system is supplying petrol to the carburetor.

The rotor arm must be pointing to number one cylinder at the top of the compression stroke of that piston, with the corresponding leads to each cylinder in the rotation of the distributor shaft - in the order of firing: 1,4,3,2.

There are quite a few variations of the air cooled boxer engine and the service manuals that cater for Type 1 and 2 vehicles, where the distributor can be 180 degrees out on the spigot (offset) drive from the camshaft. Especially with the Karman Ghia lump.

This internal combustion engine is a four stroke (Induction, Compression, Ignition, Exhaust), with two valves per cylinder. That means that each piston must travel travel up and down the bore four times to complete one cycle of the firing sequence. The flywheel stores enough energy in between the firing of each cylinder to smooth out the four controlled explosions, with more to spare for powering the vehicle.

The engine runs on petroleum, but will not handle the new C10 biofuel mix in the UK, that will most likely damage your oil seals, and those of thousands of cherished vehicles. But then petrol and diesel vehicles are to be phased out by 2030 in Europe - and that is a good thing - where global warming is concerned. Although, historic vehicles are evidence of the development of mankind, and so very important reminders of our achievements.

Working from scratch and without any knowledge of who set up the engine, where it came from, or who messed around with the spark plug leads, it is sometimes better to go back to basics.

We must then confirm that number one cylinder is on the firing stroke. To achieve this or check for correct positioning of the distributor, take out the spark plug of number one cylinder. Fit a compression gauge and rotate the engine counterclockwise, then clockwise and watch the compression gauge as the rotor reaches where it would normally send a spark via the coil. You should note a rise in pressure at Top Dead Centre (TDC) if the distributor position is correct. The notch on the crankshaft pulley will correspond with the crankcase split/line/marking as the pressure reaches its maximum.

The engine should be at normal operating temperature when setting the ignition timing with a strobe light. An experienced mechanic can sometimes tune the engine by the ear, turning the distributor until the correct sound is achieved. The rest of us mere mortals rely on a strobe.

Where there are so many variations as to gap sizes and boxer engine configurations, we started by selecting a cylinder and calling it number one. Most workshop manuals say number one cylinder is on the drivers side (right in the UK) closest to the bulkhead. Naturally, the most difficult spark plug to get to.

Unclip the distributor cap and remove the rotor arm and dust cover. You can now see the contacts. Loosen the clamp nut and undo the retaining bolt to the engine casing. You can then pry up the distributor carefully with a blunt screwdriver, such as not to damage either part. it is easier to fit new contacts in a vice with soft jaws.

SPARK PLUGS - Set the spark plug gaps to 0.6 - 0.7mm (check for the clearance for your engine).

CONTACTS - Install new contacts and set at 0.4mm. You'll need to remove the distributor cap and rotor arm.

Having

installed and gapped the new contacts, refit the distributor, making sure

the spigot dogs are aligned with the drive in the engine. It will not fit if

180 degrees out. Once fitted, turn the engine using the crankshaft pulley nut until the rotor button

is aligned with the groove in the distributor rim and the timing mark on the crankshaft pulley is aligned with the crankcase

seam - on the compression stroke of number one cylinder.

Turn the distributor body clockwise until the contacts of the ignition points are closed. Turn on the ignition switch but do not start the engine. Turn the distributor counterclockwise until the test light comes on (just as the contact points are opening) and tighten down the clamp.

After this fire her up, and check the timing using a strobe. Finally, tighten the distributor clamps and securing nuts, before driving off into the sunset with your surf board and wet suit.

...

WHO INVENTED THE IC ENGINE

Germany is where the internal combustion engine was invented by a hub of engineers all competing to produce automotive units. In 1879 Nikolaus Otto, Gottlieb Daimler and Wilhelm Maybach, patented the compressed charge, four-stroke cycle engine. In 1892, Rudolf Diesel developed the first compression ignition engine, also a four stroke (US patent # 608845 filed 1895 - granted 1898, by which time Diesel had become a millionaire. Ironically, Otto was less keen to work on automotive engines.

Petrol engines were mostly used in cars and light vans where diesel units were heavier and more expensive, so used in trucks for haulage. This is not the case now, with smaller turbocharged engines being common in cars, but particles from diesel engines are considered dangerous to humans and carbon dioxide and monoxide are greenhouse gases that helped to cause global warming and climate change, leading to acid oceans.

The good news is that we now have electric vehicles. We can thank all those automotive engineers who gave transport to the masses, so aiding the development of society. They had no idea the harm such engines might cause when in mass use. We hope it is not too late to repair some of the damage we have done to planet earth.

VINYL DESIGN - This is not a true representation of the final design, but just a quick outline to get the ball rolling and the brain cells ticking. We are considering a two-tone paint job, with vinyl lettering and some vinyl wrapped panels to keep the cost of the artwork down.

OCEAN CLEANUP PROJECTS A - Z

* Adidas * Algalita research foundation * Aliance to end Plastic Waste * Boyan Slat's ocean booms * 4Ocean recycled plastic bracelets * Earth Day ocean plastic fact sheet * Fionn Ferreira's ferrofluid extraction of microplastics * Junk Raft - plastic expedition * Plastic Oceans Canada * Plastic Oceans Org * Seabin * SeaVax autonomous drones * Surrey University PIRATE & Triton

LINKS & REFERENCE

https://bustopia.com/vw-bug-bus-tune-up-specs-info.html https://aircooledvwlove.com/how-to-set-ignition-timing-on-an-air-cooled-vw/

LOW LOADER - August 8 2019, the tour bus is collected for transport to a local spray booth for painting and oven baking. She needs rather more than the usual preparations. This is just the start of a longer journey to a good paint finish.

OVEN BAKING - 2-Pack paint is applied at normal room temperatures, then re-flowed in a low temperature oven for a better finish. We were fortunate to have a specialist restoration craftsman locally, who could help with this project. He'll be using an epoxy primer to gain a sound surface to apply a topcoat.

|

|||

|

VW HOME - BODYWORK - ENGINE - ELECTRICS - GOLF - LEATHER INTERIOR - LOGISTICS - PAINTING - PREPARATIONS SERVICING - STAINLESS STEEL - SUSPENSION & BRAKES - VINYL WRAPPING - WEDDING HIRE - WELDING

MORE COOLING PLEASE - Professor Ferdinand Porsche designed this engine for the 'People's Car,' the literal translation of 'Volks-Wagen.' The idea was to produce a car that every citizen in Germany could aspire to. The Citroen 2CV had a similar concept for French farmers. Eco cars are now far more fuel efficient and affordable - because of robotic mass production. These engines powered jeeps and amphibious vehicles in WW2 and are used in light aircraft today.

Please use our A-Z INDEX to navigate this site, where page links may lead to other sites

|

|||

|

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2020. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|

|||