Sargassum

has been at crisis levels for several years, but only recently have the Island

nations affected by what amounts to a plague, put that stamp on the problem.

Island Nations dependent on tourist dollars, to include the Gulf of Mexico

coastal towns and cities, have been hit with beaches of

decomposing sargassum, smelling of rotten eggs, attracting flies, causing ecological

mayhem and potential health hazards.

Hardly alluring for holiday makers, as they book their hotels in a formerly paradise

location. With an efficient method of harvesting the

floating seaweed, there is potential to turn a nuisance into opportunity. PLASTIC SOUP FOUNDATION 25 FEBRUARY 2021 - PACKAGING MADE OF SEAWEED: FINALLY A REAL SOLUTION FOR THE PLASTIC SOUP!

Good news! The winner of the Green Challenge of the broadcaster Omroep Max’s new TV programme Iedereen Kan Het! (anyone can do it!) has thought up a clever solution for single-use food packaging – seaweed packaging.

Ayça Dündar of SoluBlue, a British start-up, could hardly believe it when she heard that she would get half a million euros to develop her seaweed packaging. The second prize (two hundred thousand euros) went to Jiva Materials Limited that has developed a fibrous material for printing plates that dissolves in water. This makes them easier to recycle.

The prize money comes from the Dutch National Postal Code Lottery. The other finalists also did not go home empty handed.

TWO BIRDS WITH ONE STONE

By developing packaging made of seaweed, SoluBlue killed two birds with one stone. The packaging is completely biodegradable and the food that it contains stays fresh longer.

Single-use plastic food packaging has two major disadvantages. The first is that it becomes part of the plastic pollution problem as it does not break down in the environment. The second is that it often condenses on the inside. While food in plastic stays fresher for longer than unpackaged food, the contents start getting mouldy after a while.

NO FOOD WASTE

The food packed in the seaweed packaging stays fresh longer than it does in plastic packaging. Instead of forming mould, the food starts drying out and stays usable even when dried. So food does not need to be thrown away anymore while about one third of all the food currently produced around the world is wasted.

The company claims that tomatoes, for example, will stay fresh for three months. Unfortunately, the seaweed packaging is not suitable for packaging

liquids, like milk, soft drinks or smoothies.

SEAWEED PACKAGING IS EDIBLE

There is even a third advantage. The seaweed packaging is edible so it can be used for cattle feed, for example. You can also throw it on the compost and, should it end up in the environment or the sea, it will biodegrade within a few weeks. Given that the material is digestible, any animal that eats it will not suffer any negative side effects. In addition, the fact that the packaging can be thrown away with leftover food makes cooking and cleaning the kitchen a lot easier.

OIL-BASED PLASTIC IS TOO CHEAP

SoluBlue will undoubtedly use the prize money to scale up its production process. However, the production costs will remain higher than those of traditional plastic that is produced from cheap fossil fuels.

Multinationals such as Unilever and Nestlé are likely to assess the costs of the packaging and will not embrace this option quickly for this reason.

We need to move to the closed circular economy and this packaging material will be absorbed in the natural circular system. It could not be better. It is thus up to governments to push industry. Without financial measures that discourage the use of

plastic and that incentivise real alternatives, we will not see seaweed packaging on the shelves for a while. FUTURE BRIDGE 24 FEBRUARY 2022 - SEAWEED BASED PACKAGING

Changing consumer behavior due to health and environmental concerns globally has made way for growth in seaweed-based packaging.

Seaweed-based packaging as an eco-friendly replacement for plastic is quite feasible. Seaweed can grow in both seawater and freshwater, is inert, and doesn’t require any additional media for its growth. It is also packed with a plethora of vitamins, fiber, and minerals, allowing the possibility of producing edible packaging. The natural polysaccharides obtained from seaweeds such as alginates, carrageenan, ulvans, fucoidans, and laminarins are enormously significant in the film-forming ability of seaweeds. The growth and utilization of seaweed ease the waste management process as its biodegradable and the packaging can be naturally decomposed. This reduction in the production of plastic will directly contribute towards a reduction in gas emissions and the contamination of soil, water, and air. Some studies have reported that it takes a hectare of the ocean to create 40 tons of dry seaweed. During processing, that same volume can absorb 20.7 tons of CO2 emissions.

The only major drawback owing to the production of seaweed is its cost. Seaweed packaging requires manual processing to some extent and the process of scaling- up is still in pilot-scale.

SEAWEED PACKAGING STARTUPS THAT ARE THRIVING

SWAY [US]

Sway makes seaweed-based packaging an alternative to plastics. The start-up secured funding of about $2.5 million in a seed round led by Valor Siren Ventures. The funding would support the development of two compostable products, retail, and polybags. The products are set to undergo pilot trials in the upcoming year. The startup is still improving its formulation and will use its funding switch from the lab to pilot-scale production. The startup claims that the seaweed-based material has stronger tensile strength compared to low-density polyethylene, which is utilized for packaging film and grocery bags. The team has also run early tests showing that the material can quickly biodegrade in a backyard and can also be compostable. Sway bags when put into the soil can act as an excellent soil improver. Sway uses multiple species of seaweeds to vibrantly color their products, promoting the use of natural pigments as opposed to toxic dyes. Sway’s products are non-toxic, compostable, highly durable, and carbon negative.

LOLIWARE [US]

Partners and product designers Chelsea Briganti and Leigh Ann Tucker, jointly designed the edible cups made from seaweed product- agar (seaweed gel) and made them more aesthetically pleasing by adding yummy flavors such as grapefruit, vanilla, cherry, and more. They are the world’s leading seaweed material technology aiming to replace single-use plastics. The Startup has also designed biodegradable, edible straws that are made with seaweed, in a process that adheres to the principles of the circular economy. These straws come in three derivatives such as the-Blue, carbon straw, Mother of pearl straw, and the carbon delete straw. Loliware uses its proprietary technology for the production of its edible cup.

NOTPLA (UK)

Notpla is a company that makes sustainable packaging from seaweed and other plants. The products are made from seaweed which can be consumed or composted naturally. Notpla is the startup that made Ooho! And has been rebranded as Notpla which is short for not plastic. Notpla is made from renewable brown seaweed, which can grow up to 1m in the ocean without any media and the need for freshwater. Seaweeds also contribute towards the deacidification of the ocean and promote the production of oxygen by consuming carbon dioxide for its growth. The seaweed-based packaging can degrade within 4 weeks and is an excellent soil ameliorant too.

Notpla coating is also made from seaweed and is designed to make packaging made from bioplastic or plastic, a biodegradable coating that makes it greaseproof and water-resistant.

The Notpla takeaway boxes are designed to be sustainable and compostable.

Notpla oil pipettes are designed to hold oil in squeezable variants which can be kept in restaurant takeaway and lunch boxes. The Notpla films are designed to be compostable and biodegradable and can be used to pack dry and wet food consumables. They can dissolve in water and come in natural variants that are scented and flavored. They also have hot water and cold water soluble packaging sachets which can be used to pack instant coffee powders or seasoning condiments.

Notpla has a variety of products such as the Notpla sachets, Ohoo, the Notpla coating, and the Notpla takeaway boxes.

The Notpla sachets are made especially for sauces, condiments, and salad dressings. Made with seaweed they are biodegradable and can be decomposed naturally.

The capacity of these sachets is from 10 to 60ml. Notpla has partnered with Heinz ketchup.

Notpla recently received funding of $1.32 Mn, led by Horizons Ventures and with the participation of Asantor ventures, Lupa systems, and Torch capitals. The funding aims to commercialize the Ohoo and other Notpla coating and packaging.

The manufacturing machine which produces Ohoo sachets can manufacture in various ranges from 15-100ml. Once tested and scaled up, Notpla believes in expanding its business model to lease these materials and sell cartridges of the materials to food manufacturing companies to facilitate ease of manufacturing their products of sauces, condiments, and drinks in the Notpla containers.

EVOWARE (INDONESIA)

This Indonesian start-up aims to ease the waste management of plastic packaging by creating edible packaging from seaweed. Evoware’s edible packaging is environmentally friendly and nutritious as seaweed is rich in flavonoids, fiber, and antioxidants. Indonesia is the world’s second-largest contributor to ocean pollution. Most of the waste found here comes from plastic food containers and packaging. Evoware makes food packaging and containers which are made of indigenous seaweed. This edible packaging is biodegradable, packed with nutrients and if disposed of, can be an excellent soil ameliorant. Evoware products are certified halal, which is significant for Muslim populations, wherein a majority of the Indonesian population are concerned. It doesn’t contain any animal derivative and is suitable for vegetarians and vegans. Evoware’s products are made from seaweed, which doesn’t require arable land for its cultivation. Seaweed grows without the necessity for the addition of media. Seaweed improves air quality as they absorb

carbon dioxide to produce

oxygen.

Evoware sources its seaweed locally from Indonesian farmers and hence improves the livelihood of seaweed farmers.

They have launched multiple products such as the Ello jello cups, seasoning sachets, burger wraps, single-serving instant coffee powder sachets, and also for packaging non-food products such as straws, sanitary napkins, soaps, and toothpicks. The Ello jello cups come in exciting flavors such as green tea, lychee, and orange. The food wraps and edible sachets are colorless, odorless, and inert and hence can be used to pack flavorful seasonings. The edible seasoning sachets can be used directly as they dissolve into hot water, without interfering with the taste of the final product. The company was founded in 2016 and its headquarters is in Jakarta, Indonesia.

PRODUCTION OF PACKAGING FROM SEAWEED

Fossil fuels can be explored for the production of biodegradable polymers such as polylactic acid (PLA) and polyhydroxy butyrate (PHB) that is degraded by certain microorganisms and can be returned to nature in some time. On the other hand, bio-based plastics are essentially made from biological resources such as polysaccharides/protein and other polyesters extracted from plants, and marine organisms. These bio-based polymers are degraded easily and are non-toxic in nature. Seaweed is inherently rich in antioxidants, fibers, and polysaccharides that are strong and resilient. The combination of seaweed along with certain biodegradable polymers could offer a sustainable and superior advantage to packaging materials compared to conventional ones. The major advantage of seaweed-based packaging materials is that they can be made edible without the use of any adulterants or preservatives.

The properties of natural edible films can be enhanced by the addition of aromatic substances, flavor-enhancing agents, nutritional substances, antioxidant agents, or antimicrobial agents.

Conventional methods for the production of seaweed packaging included the usage of chemicals and heat treatment to extract the polysaccharides from that seaweed. Latest technologies use benign fermentation to promote the extraction of polysaccharides without the use of harsh chemicals. The yeast residues post-fermentation are used as animal residue, facilitating a circular economy without any wastage.

REASONS TO SWITCH FROM PLASTICS TO EDIBLE SEAWEED PACKAGING

Customers prefer edible seaweed packaging over plastic ones due to this reason:

High consumption of processed, ready-to-eat foods: Global urbanization has created jobs and has improved the lifestyle of many individuals. This adds to a fast-paced life which in turn increases the dependence on processed food. Processed foods generally come in plastic packaging which can be highly polluting. This has resulted in an increase in demand for sustainable, edible, seaweed-based packaging.

Rise in hygiene conditions: Plastic causes pollution, this has motivated people to promote the production and use of edible packaging that can be eaten or composted. This can prevent various community and infectious diseases.

Elimination of waste cycle: Plastic waste needs to be either recycled, reused or usage should be reduced. But mostly in developing countries, the waste is either incinerated or dumped in landfills. This can be the cause of groundwater leaching, harmful air, and soil pollution. Edible packaging does not require either of the waste management roles. The edible packaging can be consumed or it can be composted. Edible packaging can be fortified with vitamins and minerals and can be made more palatable with different flavors.

Environmental Reasons: The production of plastic-based packaging requires fossil fuel, the world’s annual consumption of plastic materials has increased from approximately five million tonnes in the 1950s to nearly 230 million tonnes today. The amount of non-biodegradable waste generated is incomprehensible. Plastic food packaging is the most significant contributor to plastic waste. The necessity of seaweed-based edible packaging is extremely important owing to these conditions. Managed effectively, it may be possible to reduce the negative impact of

sargassum and even benefit from this environmental nuisance.

LINKS https://seaweedpackaging.com/2018/09/25/seaweed-based-packaging/ https://www.futurebridge.com/seaweed-based-packaging/ https://www.plasticsoupfoundation.org/en/2021/02/packaging-made-of-seaweed-finally-a-real-solution-for-the-plastic-soup/

|

|

UNEP

- UNITED

NATIONS ENVIRONMENT PROGRAMME

While 2020 was relatively mild in terms of sargassum volumes, and a global pandemic

became the overarching worry, 2018 was record breaking in terms of sargassum

volumes reaching Caribbean shores and 2019 was also significant. Floating sargassum should not be construed as negative in and of itself – it is beneficial at sea, mainly as a unique pelagic habitat. However, the mass stranding of sargassum on coastlines has significant negative

impacts (biophysical and socio-economic), particularly on coastal communities and

livelihoods, public health, tourism and fisheries. This issue therefore represents an

emerging hazard for a region that is already subject to numerous hazards. Indeed,

various countries in the Caribbean have declared national states of emergency with

respect to sargassum influxes (Desrochers et al. 2020).

The issue is however not confined to the Caribbean

Sea, but it extends across the Tropical Atlantic, including equatorial Brazil as well as coastal West Africa from Sierra Leone through the Gulf of Guinea. Sargassum influxes are very much a multi-regional transboundary issue, demanding coordination and collaboration within and across impacted regions.

HEAVY MACHINERY

A secondary, avoidable negative impact of the influxes relates to the use of heavy machinery to remove massive Sargassum landings, which impacts beach habitats and tend to worsen the environmental harm. The use of heavy machinery causes compaction of beaches and kills organisms that live in the sand, such as ghost crabs and other sea creatures that keep a beach healthy by creating hundreds of holes that keep the beach ventilated. Driving with heavy equipment will not only crush them, but also kills any potential sea

turtle nests. Another impact is the removal of vast quantities of sand, resulting in unintentional sand mining, and ends up affecting the entire beach ecosystem.

SOCIO-ECONOMIC IMPACTS

Sargassum influxes negatively impact human well-being, activities, and livelihoods as well as major sectors of Caribbean Economies. Key sectors impacted include: coastal living and livelihoods, marine transport/ navigation, public health, fisheries and tourism. These impacts are inter-related, with many stemming from one of the key drivers of biophysical impacts – the decay of the sargassum biomass. The production of hydrogen sulphide negatively impacts

air quality, results in very unpleasant odours, and prolonged exposure is unhealthy, especially for persons with underlying respiratory conditions. This is detrimental for coastal residents and beach users, whether local or visitors.

Beach users who live elsewhere have the option to avoid impacted locations, while residents may be unable to avoid prolonged exposure. Large quantities of sargassum also spoil the aesthetic appeal of Caribbean beaches, and inhibit access to nearshore waters. Both issues affect residents, local beach users and tourists, while the latter particularly impacts those whose livelihoods rely on the sea, such as fishers who may need to access the water to access their equipment and/or livelihood.

DECLARATION OF EMERGENCY

When stranded in coastal areas, the sargassum itself dies, and many of the negative impacts originate with its decay. Given the scale and extent of the negative impacts these influx events may be characterized as a recurring hazard. The unprecedented scale of the Sargassum influxes also led to declaration of emergency conditions in several Caribbean countries e.g. Tobago in 2015, Barbados in 2018, and Mexico in 2019 (Chavez et al. 2020).

|

|

OCEAN

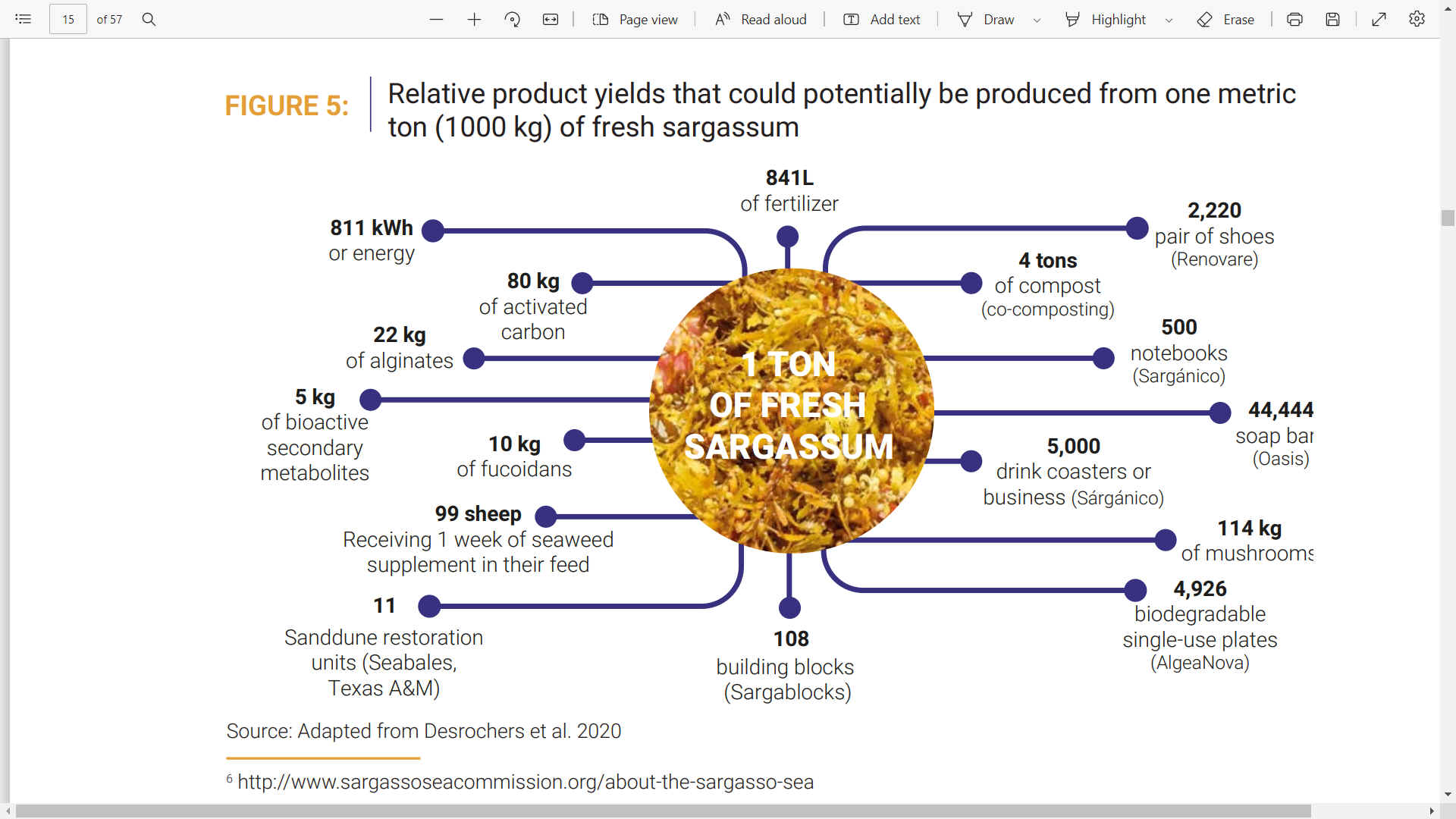

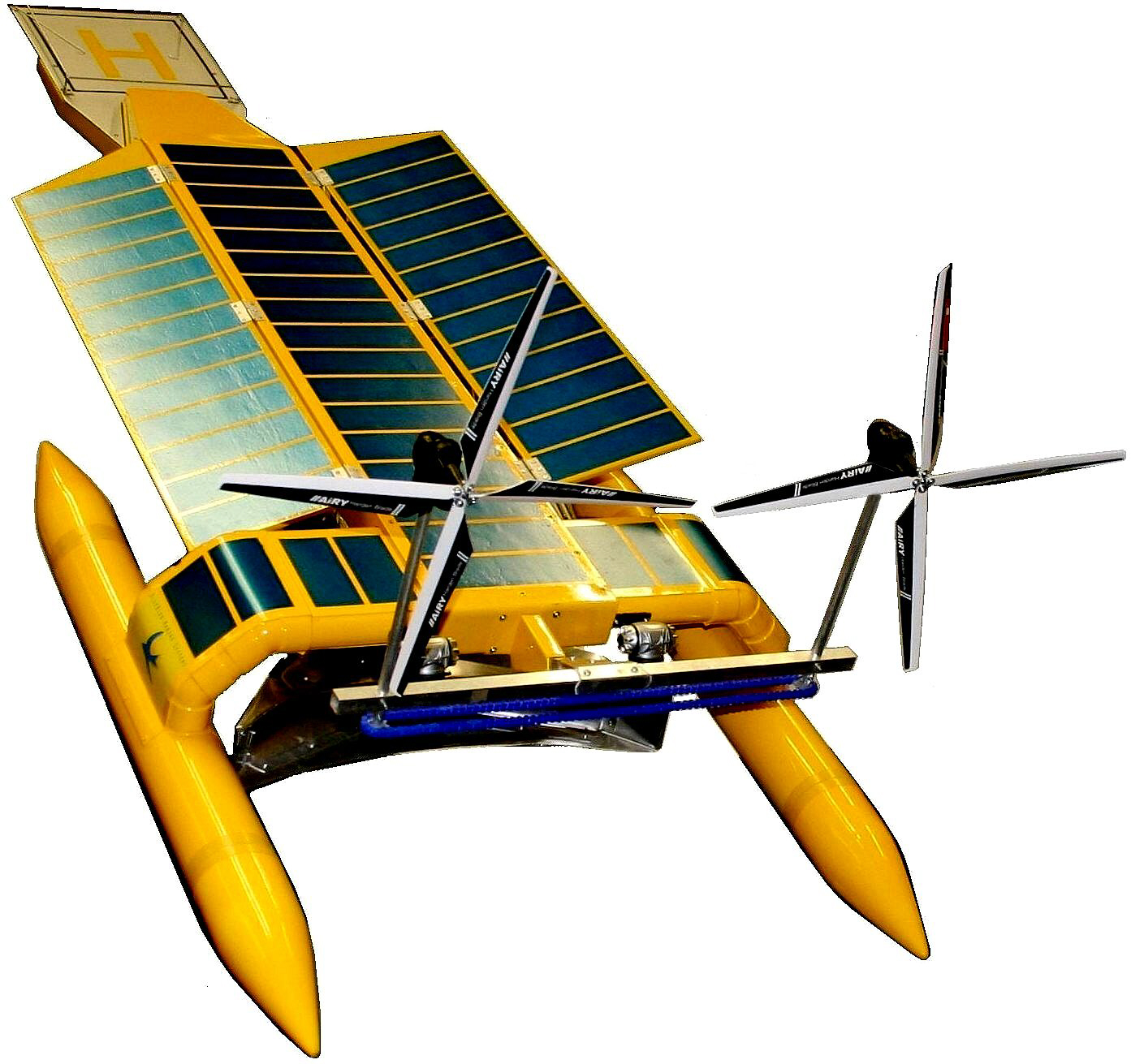

CLEANING DRONE - As seen above, SeaVax is not suitable for harvesting

sargassum in voluminous quantities. But the concept, or the equivalent, may be adapted

(or specialliy developed) for the

task. You'd still need autonomous fleet control, satellite comms and ocean

current geodata, solar assistance and a

capacious holding tank. But, the harvesting mechanics are different, as is

the pickup head and transfer arrangements. Also assuming 24 hour operations, and factory ships to

treat the recovered asset, for distribution across the globe. Then there is

carbon sequestration. But who would pay for that? Nobody in power - that's for

sure. It's all about the money for them- and they want a free lunch!

It would take a fleet of 300 specially adapted SeaVax

machines, operating at a speed of one load per hour, to deal with 22 million

tons of biological material. From our experience where we asked for funding to clean the ocean of plastic,

it will be a massive uphill struggle - with fruitless lobbying efforts - to

match the non-progress at Climate

Conferences (FLOPS). It will take a working lifetime, unless, the problem

becomes so great, that government react as if they were at war. And it is a

war. Make no mistake. It's a struggle for the survival of our great grand

children. We cannot stop our children suffering, because of corruption and

irresponsible fossil fuel companies. We are too late for that, but with more

Great Thunberg's, we might save the human race.

The sparkle on

the newly brown tinged horizon is that sargassum can be a cash crop. Even so, the

sums being bandied about don't come close to managing this crisis. What they

need is a miracle, dealing with the root cause, which is warming

of the oceans from climate

change. Sadly, the cure for rising

sea temperates is a million miles away, with present G20

policy stagnation - that stinks - like the hydrogen sulfide from rotting

seaweed.

CARIBBEAN

ISLANDS BY POPULATION

1 Cuba 11,252,999

2 Haiti 11,263,077

(Hispaniola)

3 Dominican

Republic 10,766,998 (Hispaniola)

4 Puerto

Rico (US) 3,508,000

5 Jamaica 2,729,000

6 Trinidad

and Tobago 1,357,000

7 Guadeloupe (France)

405,000

8 Martinique (France)

383,000

9 Bahamas 379,000

10 Barbados 283,000

11 Saint

Lucia 172,000

12 Curaçao (Netherlands)

157,000

13 Aruba (Netherlands)

110,000

14 Saint

Vincent and the Grenadines 110,000

15 United

States Virgin Islands 105,000

16 Grenada 104,000

17 Antigua

and Barbuda 89,000

18 Dominica 71,000

19 Cayman

Islands (UK) 59,000

20 Saint

Kitts and Nevis 46,000

21 Sint

Maarten (Netherlands) 39,000

22 Turks

and Caicos Islands (UK) 37,000

23 Saint

Martin (France) 36,000

24 British

Virgin Islands (UK) 31,000

25 Caribbean

Netherlands 26,000

26 Anguilla (UK)

14,000

27 Saint

Barthélemy (France) 10,000

28 Montserrat (UK)

5,000

29 Tortuga 25,936

30 Roatán 110,000

Governments

might revise their policies, to most urgently curb global

warming, hence ocean temperature rises that are causing the sargassum

crisis. The is the root cause of the problem. Cleaning up the excess from the

oceans and seas, is retrospective handling. That, unfortunately, it seems we

will be lumbered with for at least 50 years hence.

|