|

ENGINEERING COSTS MICROPLASTICS CLEANING

PLEASE USE OUR A-Z INDEX TO NAVIGATE THIS SITE OR RETURN HOME

|

|||

ENGAGING

YOUTH IN STEM EXPLORATION

- FIRST® LEGO® League introduces STEM (science, technology, engineering, and math) to children ages 4-16 (varies by region) through fun, exciting hands-on learning.

According to the Organization for Economic Cooperation and Development (OECD), global plastic production has now surged to 400 million metric tons annually, yet only 9% of plastic waste is effectively recycled worldwide. The rest—91%—ends up in landfills, incinerators, or natural environments, where it pollutes ecosystems, leaches toxins, and breaks down into harmful microplastics. North America, for instance, recycles just 5% of its plastic waste, while Europe leads globally at a still-low 15%. Without intervention, production is projected to rise 70% by 2040, worsening the crisis (OECD, 2022). According to UNCTAD, the volume of plastic exports grew from 218 million tons (MT) in 2005 to 344 MT in 2022. To illustrate, it would take 17.2 million trucks, each carrying 20 tons, to deliver the 2022 global plastics exports to their destination, if carried on road.

THE ENGINEERING CHALLENGE

Engineering is all about cost. How to make a product that works at a price to make it economically viable.

That comes down to efficient design. Using exotic materials is a no, no. That is why ships are built of steel, not titanium. Steel is cheap and gets the job done. In the marine world, 5083 alloy is better for smaller performance vessels. Costing about double to produce over steel. But with a longer working life, and being fully recyclable. But then so is steel.

Cheap filtration is the challenge, coupled with free energy for waste treatment and transport to reprocessing stations or ships. Thus any design would first need to evaluate the energy needed for filtration extraction, then design a vessel large enough to collect sufficient energy to be practical. Finally, you need to know how many units might stand some kind of chance of cleaning the ocean.

Hence:

1. Work out the area of ocean to be filtered clean (the geographical gyres). 2. Find the plastic hot spots (the mother load) to reduce effective area of ocean to be filtered. (We found this to be rivers) 3. Define a practical size for a filtration "Unit." (i.e. big and cheap enough to scoop say 50 tons or as your calculations indicate) 4. Build a small test model to define the energy needed per kilogram of harvested plastic. 5. The model test results from 4., tell you the solar panel area necessary for ocean cleaning operations. 6. Scale up results to something like 50 tons capacity (or as your calculations indicate) 7. Calculate number of 'Units' to make a dent on cleaning the ocean. 8. Work out cost of build and launch of each 'Unit.' 9. Design cost-effective long-term service and repair/recovery units. 10. Understand the ocean and currents to plan a best cleaning strategy.

Please note: these are the thoughts of the writer, a practical engineer and boat builder, not Cleaner Ocean Foundation or the Eagle Tech Titans. Though, hopefully, useful guidelines.

Using the above formula, the Foundation calculated at least 300 SeaVax (or equivalent) Units would be needed to keep pace with ocean plastic dumping. Around One hundred and twenty of those units would need to be stationed outside the 12 dirtiest rivers in the world. The "Dirty-Dozen."

The Foundation calculated that each SeaVax equivalent Unit could be mass produced (not for profit) for around $6 million dollars in 2016 (probably $9 million in 2025). Including ghost fishing net harvesting, intelligent filtration, satellite feedback for hotspot identification, and autonomous fleet navigation control. Setup cost (CapEx, not including prototype development) would then be around $1,800,000,000. Or, $1.8 billion US dollars (in 2016). Not to be implemented as one great big launch, but as smaller trials of say ten Units stationed adjacent to the most polluting river(s).

Then as the results indicate measurable recovery, gradually extending operations to other plastic hotspots.

Even as a data gathering machine, SeaVax (or equivalent) machines might extend mankind's knowledge of the polluted marine environment. Sending valuable geodata to environmental organizations the world over.

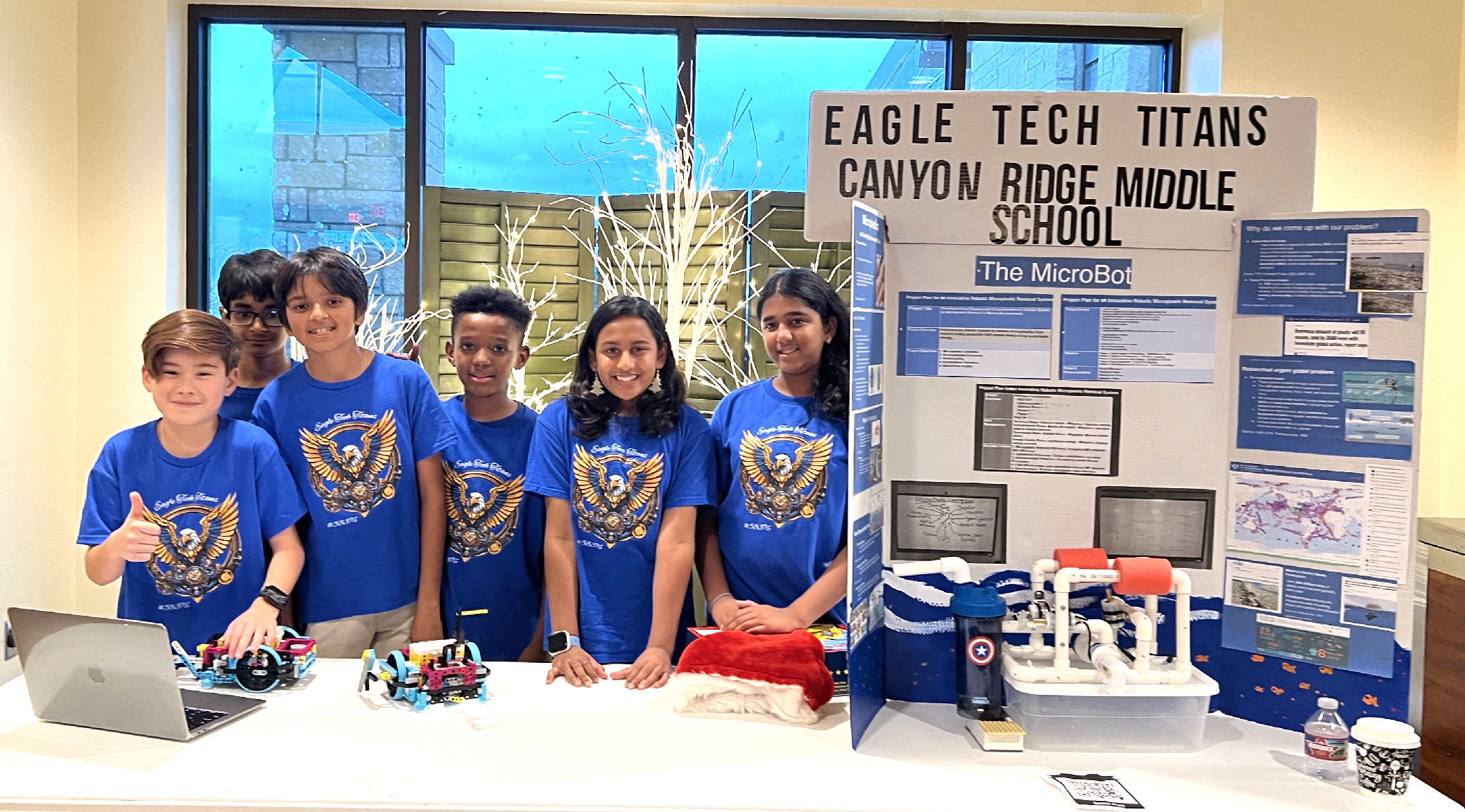

The EagleTechTitans displaying their 'MicroBot' with informational boards about plastics in the ocean and the technological challenge.

OCEAN CLEANUP PROJECTS

* Adidas * Algalita research foundation * Aliance to end Plastic Waste * Boyan Slat's ocean booms * Fionn Ferreira's ferrofluid extraction of microplastics * LEGO Eagle Tech Titans, micro plastic robot, Texas * 4Ocean recycled plastic bracelets * Plastic Oceans Canada * Plastic Oceans Org * Seabin * SeaVax autonomous drones * Surrey University PIRATE & Triton

LINKS & REFERENCE

https://www.firstinspires.org/robotics/fll https://www.oecd.org/en/topics/plastics.html https://news.un.org/en/story/2024/12/1157646 https://news.un.org/en/story/2024/12/1157646 https://www.oecd.org/en/topics/plastics.html https://www.firstinspires.org/robotics/fll

|

|||

|

PLEASE USE OUR A-Z INDEX TO NAVIGATE THIS SITE

|

|||

|

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2024. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|